Lead Performer: Alcoa - Pittsburgh, PA

DOE Funding: $1,123,838

Cost Share: $280,960

Project Term: October 2014 – September 2016

Funding Opportunity: Building Energy Efficiency Frontiers and Incubator Technologies (BENEFIT) - 2014 (DE-FOA-0001027)

Project Objective

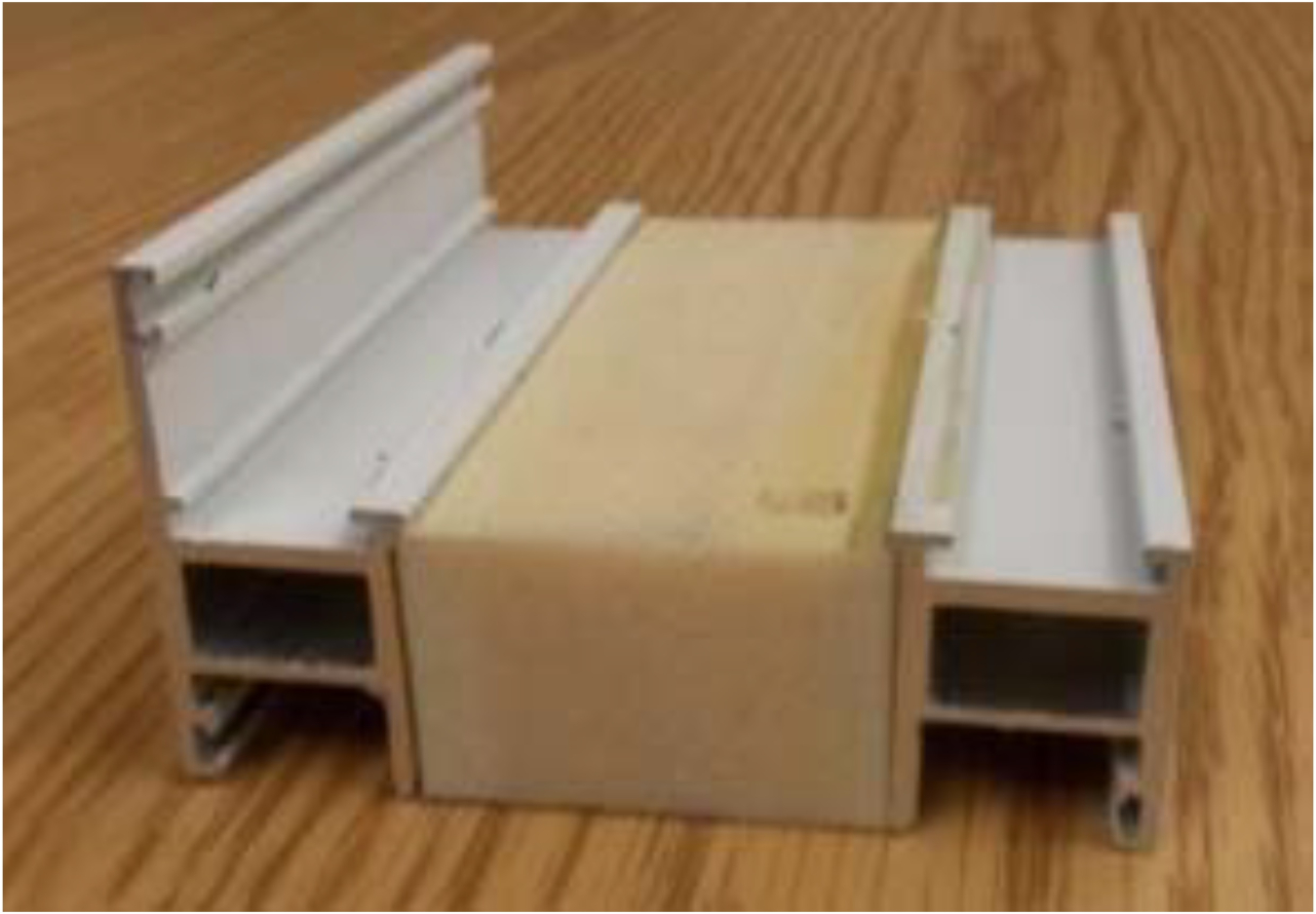

Alcoa proposes to develop a novel sandwich-type foam thermal-break technology for aluminum frame and its manufacturing process that would enable cost-effective R7 or better commercial-window systems to serve new and retrofit construction markets.

Project Impact

Success of this project would lead to the development and commercialization of the highest performance commercial window with R7 thermal performance. It would be at the same or lower cost point as the current market leading R5 OptiQ ultra-Thermal windows from Alcoa Kawneer).

The proposed thermal break technology improves the Frame U-Factor by 20% and overall window U-Factor by 15% when compared to the best commercial window in the market today (R5 OptiQ-Ultra Thermal Windows). Windows incorporating the foam-based sandwich-type thermal-break would achieve U-Factor of 0.14 Btu/hr-ft2-F (R7 or better) with center-of-glass U-Factor of 0.12 and visual-light-transmission (Vt) higher than 0.40.

These highly insulating cost-effective commercial windows would help toward achieving DOE Building Technology Office’s (BTO) goal of delivering 50% primary energy savings in the year 2030, relative to the baseline energy consumption projected by the 2010 Annual Energy Outlook.

Contacts

DOE Technology Manager: Karma Sawyer

Lead Performer: Sneh Kumar, Alcoa