-- This project is inactive --

Abengoa, under the Baseload CSP FOA, demonstrated a 100-megawatt electrical (MWe) central receiver plant using nitrate salt as the receiver coolant, thermal storage medium, and heat transport fluid in the steam generator.

Approach

Abengoa planned to operate the plant at full load for 6,400 hours each year using only solar energy. The team worked to create a team of suppliers capable of deploying a commercially ready nitrate salt central receiver technology that can be competitive in the current power marketplace.

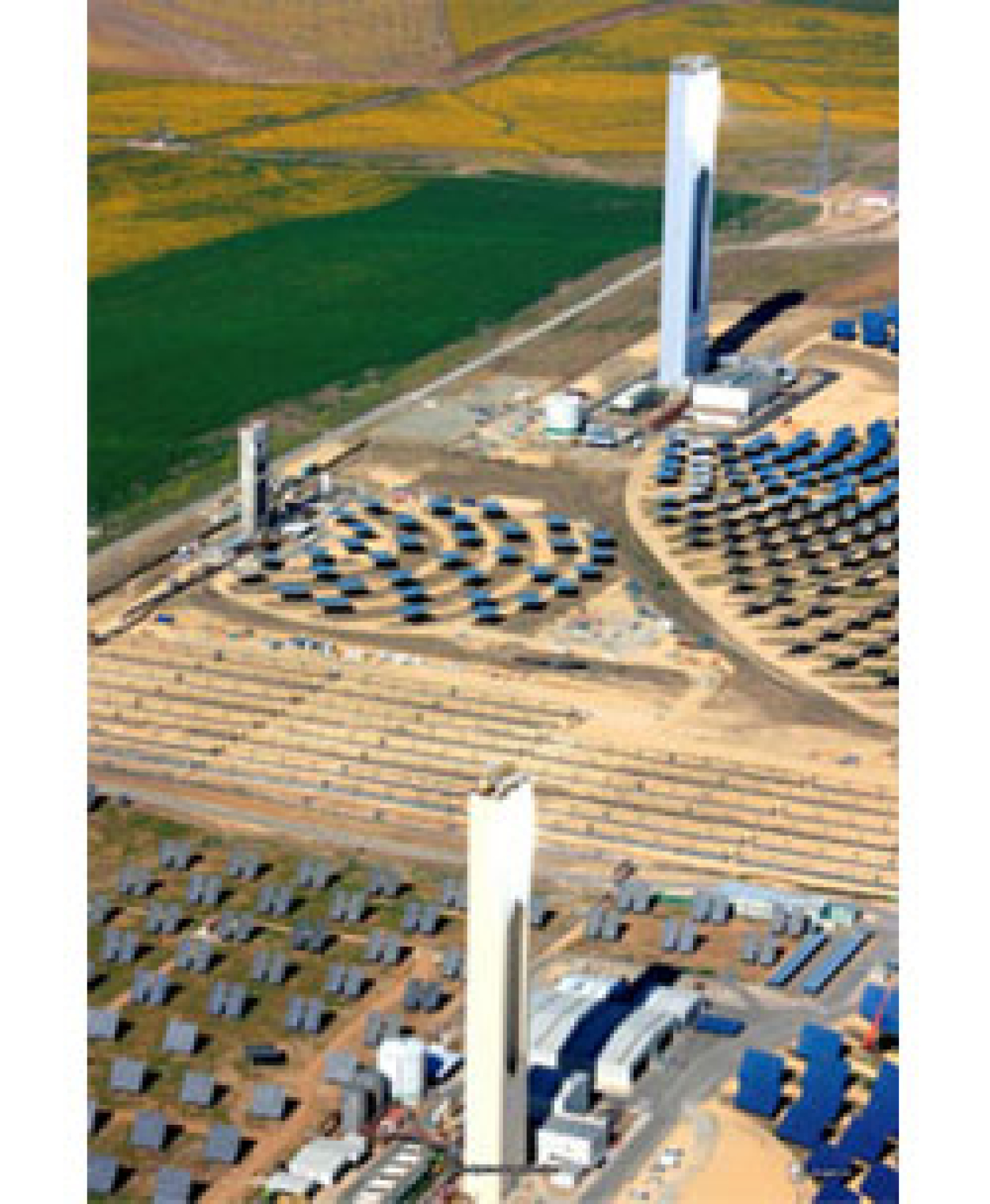

Commercial central receiver plant designs.

Innovation

Abengoa developed a new molten-salt power tower technology with a surround heliostat field. Key components include:

- A new high-temperature molten salt receiver based on a fossil boiler and heat exchanger design that will be more robust and more manufacturable

- A cermet, high-temperature, low-emissivity selective coating for central receivers that is stable when exposed to air

- An optimized surround heliostat field

- An optimized thermal storage, steam generator, and power cycle configuration based on dry cooling.

Conclusion

The first phase of the project focused on developing a baseline design for a molten salt tower and validating areas for improvement. Tasks included a market study, receiver design, heat exchanger design, preliminary heliostat design, solar field optimization, baseline system design (including PFDs and P&IDs), and detailed cost estimate. The baseline plant met the initial goal of less than $0.14/kWhe, and reinforced the need to reduce costs in several key areas to reach the overall $0.09/kWhe goal. The major improvements identified from Phase I were: 1) higher temperature salt to improve cycle efficiency and reduce storage requirements, 2) an improved receiver coating to increase the efficiency of the receiver, 3) a large receiver design to maximize storage and meet the baseload hours objective, and 4) lower cost heliostat field.

The second phase of the project investigated advancing the baseline tower with the identified improvements and included key prototypes. To validate increasing the standard solar salt temperature to 600°C a dynamic test was conducted at Sandia. The results ultimately proved the hypothesis incorrect and showed high oxide production and corrosion rates. The results lead to further testing of systems to mitigate the oxide production to be able to increase the salt temperature for a commercial plant.

Foster Wheeler worked on the receiver design in both Phase I and Phase II, investigating both design and lowering costs utilizing commercial fossil boiler manufacturing. The cost and design goals for the project were met with this task, but the most interesting results had to do with defining the failure modes and looking at a “shakedown analysis” of the combined creep-fatigue failure. A separate task also looked at improving the absorber coatings on the receiver tubes that would improve the efficiency of the receiver. Significant progress was made on developing a novel paint with a high absorptivity that was on par with the current Pyromark, but shows additional potential to be optimized further. Although the coating did not meet the emissivity goals, preliminary testing the new paint shows potential to be much more durable, and potential to improve the receiver efficiency through a higher average absorptivity over the lifetime. Additional coatings were also designed and modeled results meet the project goals, but were not tested. Testing for low cycle fatigue of the full length receiver tubes was designed and constructed, but is still currently undergoing testing.

A novel small heliostat was developed through an extensive brainstorming and down select. The concept was then detailed further with inputs from component testing and eventually a full prototype was built and tested. This task met or exceeded the accuracy and structure goals and also beat the cost goal. This provides a significant solar field costs savings for Abengoa that will be developed further to be used in future commercial plants. Ultimately the $0.09/kWhe (real 2009 $) and 6,400 hours goals of the project were met.

Final Report

Tilley, Drake, Bruce Kelly, and Frank Burkholder. Baseload Nitrate Salt Central Receiver Power Plant Design. No DE-EE0003596. 2014. doi:10.2172/1165353.

Publications, Patents, and Awards

- Alan M. Kruizenga, William Kolb, Ron J. Briggs, Joshua Christian, Daniel Ray, David Gill, John Kelton, Kye Chisman. Loop for the Observation of Film Temperature Effects on Decomposition (LOFTED). SAND2014-18103

Learn about other concentrating solar power research.