Teams with innovative ideas to reduce electronics waste compete to win prizes.

Advanced Materials & Manufacturing Technologies Office

January 8, 2025Prize Name: Electronics Scrap Recycling Advancement Prize (E-SCRAP)

Federal Funds Amount: Up to $3.05 million in total cash prizes and $900,000 in national laboratory analysis support

Description

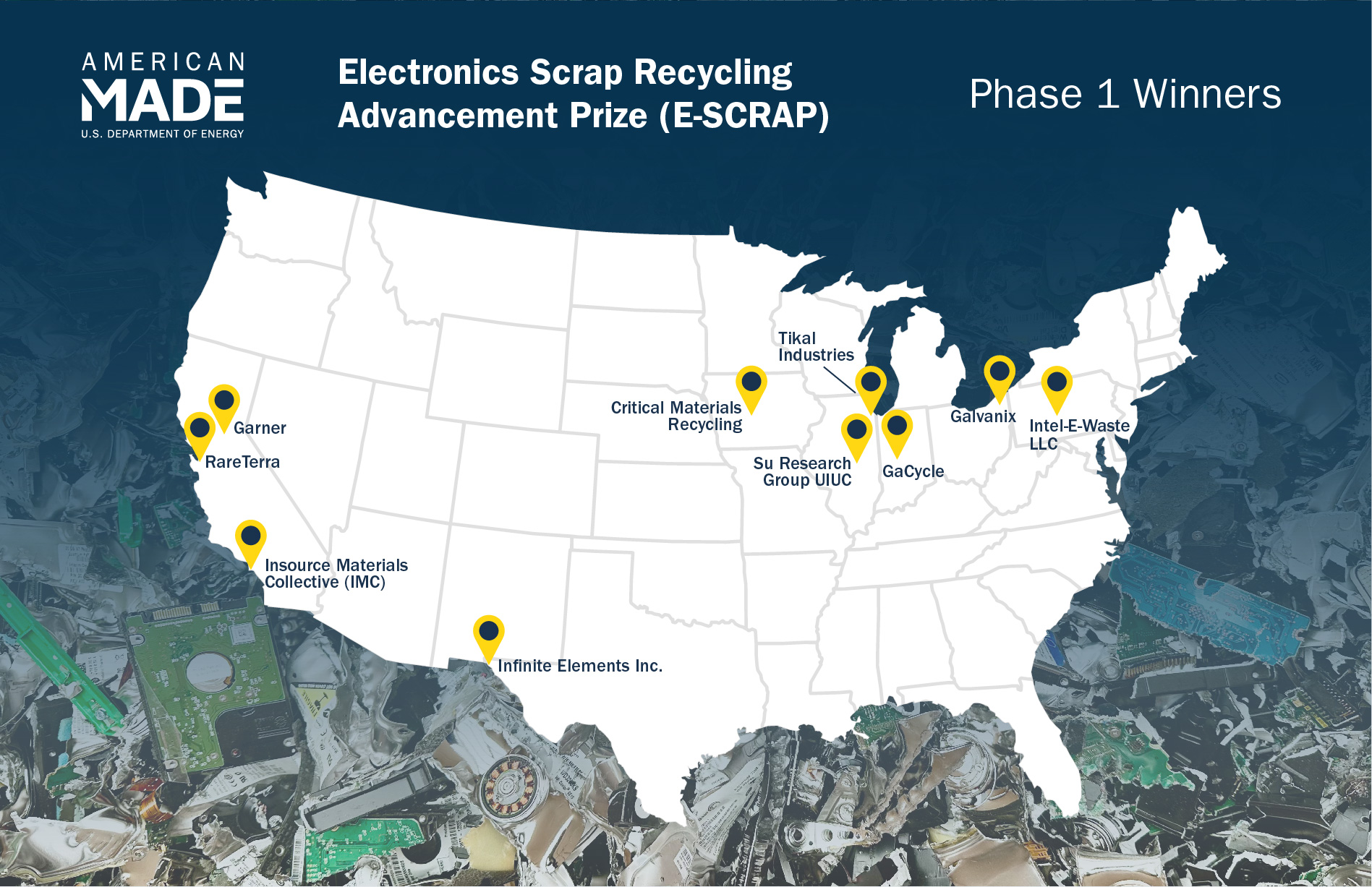

In January 2025, the U.S. Department of Energy (DOE) announced the 10 teams from seven states who won Phase 1: Incubate of the Electronics Scrap Recycling Advancement Prize. Phase 2 is currently open to new and returning participants.

The E-SCRAP prize, which launched on March 6, 2024, is a three-phase competition that will award up to $4 million to competitors to substantially increase the production and use of critical materials recovered from electronics scrap—or e-scrap.

E-scrap—which includes mobile phones, home appliances, medical or office equipment, and anything else powered by electricity—represents the fastest-growing waste stream globally, with e-scrap generation expected to double 2014 levels by 2030.

Only 17.4% of e-scrap was collected and recycled globally in 2019, discarding 83% of e-waste and $57 billion in raw material value. However, e-scrap recovery faces numerous roadblocks, including a fragmented recycling value chain, a complex and dynamic feedstock, and a rapidly evolving end-use market.

This prize encourages new ideas that enhance the recovery of critical materials along the recycling value chain from end-of-life products to reintroduction. Innovation is also needed to help integrate the separation technologies into the recycling value chain.

E-SCRAP is led by DOE’s Office of Energy Efficiency and Renewable Energy’s Advanced Materials and Manufacturing Technologies Office (AMMTO) and managed by the National Renewable Energy Laboratory.

Phase 1 Winners

During Phase 1, competitors proposed solutions to substantially increase or expand the amount of critical materials recovered from e-scrap to be used in U.S. manufacturing.

Number of Phase 1 Winners: 10

Number of States Containing Selected Projects: 7

Phase 1 Federal Funding Amount: $500,000 in cash and $300,00 in technical assistance from a national laboratory

Phase 1 Winning Projects

Winners of the Electronics Scrap Recycling Advancement Prize are located in California, Texas, Iowa, Illinois, Indiana, Ohio, and Pennsylvania.

Click on each project (and team) name to view the location and project innovation. Each project received $50,000 in cash and $30,000 in technical assistance from a DOE national laboratory.

Location: El Paso, Texas

Description: Infinite Elements has developed a multistep process, including granulation, mechanical sorting, and bioleaching, that allows for maximum recovery and recycling of e-waste that’s made up of mixed materials.

Location: Roseville, California

Description: Garner’s DiskMantler uses shock, harmonics, and vibration to disassemble hard disk drives and solid-state drives into their critical rare earth elements (REEs), creating a clean waste stream that’s ready for responsible recycling.

Location: Chicago, Illinois

Description: Tikal Industries’ Bluerock Filtration system is a deionization-based process that can be integrated into existing e-waste recycling processes to optimize the selective recovery of critical materials needed in renewable energy, consumer electronics, and electric vehicle applications.

Location: Berkeley, California

Description: RareTerra is developing an environmentally friendly bioplatform capable of selectively solubilizing, accumulating, and separating rare earth elements (REEs) from e-scrap. This process will reduce sorting requirements, eliminate the need for harsh acids, and concentrate metals of interest.

Location: Rancho Palos Verdes, California

Description: Insource Materials Collective is developing a novel recycling process for transforming discarded neodymium-iron-boron magnets into ones that can be put directly put back into the service chain—without requiring any feedstock preprocessing.

Location: Boone, Iowa

Description: Critical Materials Recycling is using eco-friendly acid-free dissolution recycling technology to recover REEs from low-value e-waste sources, increasing their value and thereby incentivizing greater capture and recycling. This process also enables comprehensive recycling of all materials within the feedstock, including precious metals, aluminum, plastics, steel, and more.

Location: West Lafayette, Indiana

Description: GaCycle has developed a microorganism-based solution to extract gallium from common e-waste products made with gallium arsenic or gallium nitride. The method will yield higher gallium recovery rates than traditional acid-leaching processes.

Location: Urbana, Illinois

Description: Professor Xiao Su and a group of University of Illinois students developed a novel electrochemical separation process that uses minimal energy to recover high amounts of platinum group metals from e-waste.

Location: State College, Pennsylvania

Description: The Recycling E-Scrap with Adaptive Capacity Technology’s patented low-cost, chemical-free, and scalable recycling process maximizes recovery of critical materials and high-quality plastics from e-scrap.

Location: Cleveland, Ohio

Description: Galvanix has developed a novel process to recover REE from magnet scrap using a selective leaching process followed by a sustainable molten salt electrolysis process that yields new, high-quality magnets.

Join Phase 2

Eligible participants to compete in Phase 2: Prototype must adhere to the following requirements:

- Competitors can include winners and nonwinners from Phase 1 as well as new competitors.

- Competitors must be a for-profit business entity, such as a corporation or other organization that is formed in and maintains a primary place of business in the United States. Individuals or groups of individuals are not eligible to compete.

- Winning nonfederal government entities from Phase 1 will need to partner with a private entity.

- Winning individuals from Phase 1 will need to form a legal for-profit private entity to participate in Phase 2.

Key Dates

| Stage | Date |

| Phase 2 Opens | January 2025 |

| Phase 1 Selections Announced | January 2025 |

| Phase 2 Submissions Closes | September 2025 |

| Phase 2 Selections Announced | October 2025 |

| Phase 3 Opens | October 2025 |

Learn More and Get Involved

- Visit the American-Made website for this prize.

- Access the full rules

- Follow this prize on HeroX to get updates.

- Sign up for the Manufacturing Moment newsletter to stay current with the latest news.

-

This past year, AMMTO has advanced projects and technologies that will generate impact for next-generation American manufacturing for energy technologies and systems. Take a look at our portfolio of successes.January 17, 2025

This past year, AMMTO has advanced projects and technologies that will generate impact for next-generation American manufacturing for energy technologies and systems. Take a look at our portfolio of successes.January 17, 2025 -

- Critical Materials and Minerals

The Critical Materials Collaborative shares news, events, and opportunities from the end of 2024.January 15, 2025 -

- Circular Economy and Sustainable Manufacturing

- Clean Energy

- Advanced Manufacturing Processes

- Supply Chains

- Energy Efficiency

Ten teams receive a collective $1.5 million and Phase 3 opens to returning competitors.January 14, 2025 -

- Critical Materials and Minerals

Teams with innovative ideas to reduce electronics waste compete to win prizes.January 8, 2025

Sign up to get the latest news on advanced materials and manufacturing news and opportunities, like this prize.