Hanford Site contractors are busy preparing for a second Direct-Feed Low-Activity Waste Program campaign after the site’s 222-S Laboratory evaluated waste feed for the first DFLAW campaign, ensuring the waste is suitable to be treated for vitrification.

Office of Environmental Management

December 10, 2024Navarro-ATL scientists prepare a slurry of treated tank waste and glass-forming compounds that were used to create a laboratory-scale test of vitrified tank waste.

RICHLAND, Wash. — Hanford Site contractors are busy preparing for a second Direct-Feed Low-Activity Waste (DFLAW) Program campaign after the site’s 222-S Laboratory evaluated waste feed for the first DFLAW campaign, ensuring the waste is suitable to be treated for vitrification.

The laboratory, operated by Navarro-ATL, plays a key role in Hanford’s DFLAW Program, which will vitrify, or immobilize in glass, and dispose of low-activity waste from Hanford’s underground waste storage tanks.

"Hanford engineers have determined that DFLAW waste samples will need to be evaluated by the lab in less than 90 days to keep operations running,” said Jeff Cheadle, Hanford Field Office 222-S Lab Program manager. “The 222-S Laboratory completed its most recent evaluation in 75 days, demonstrating it is ready to meet the necessary pace of this critical waste treatment mission."

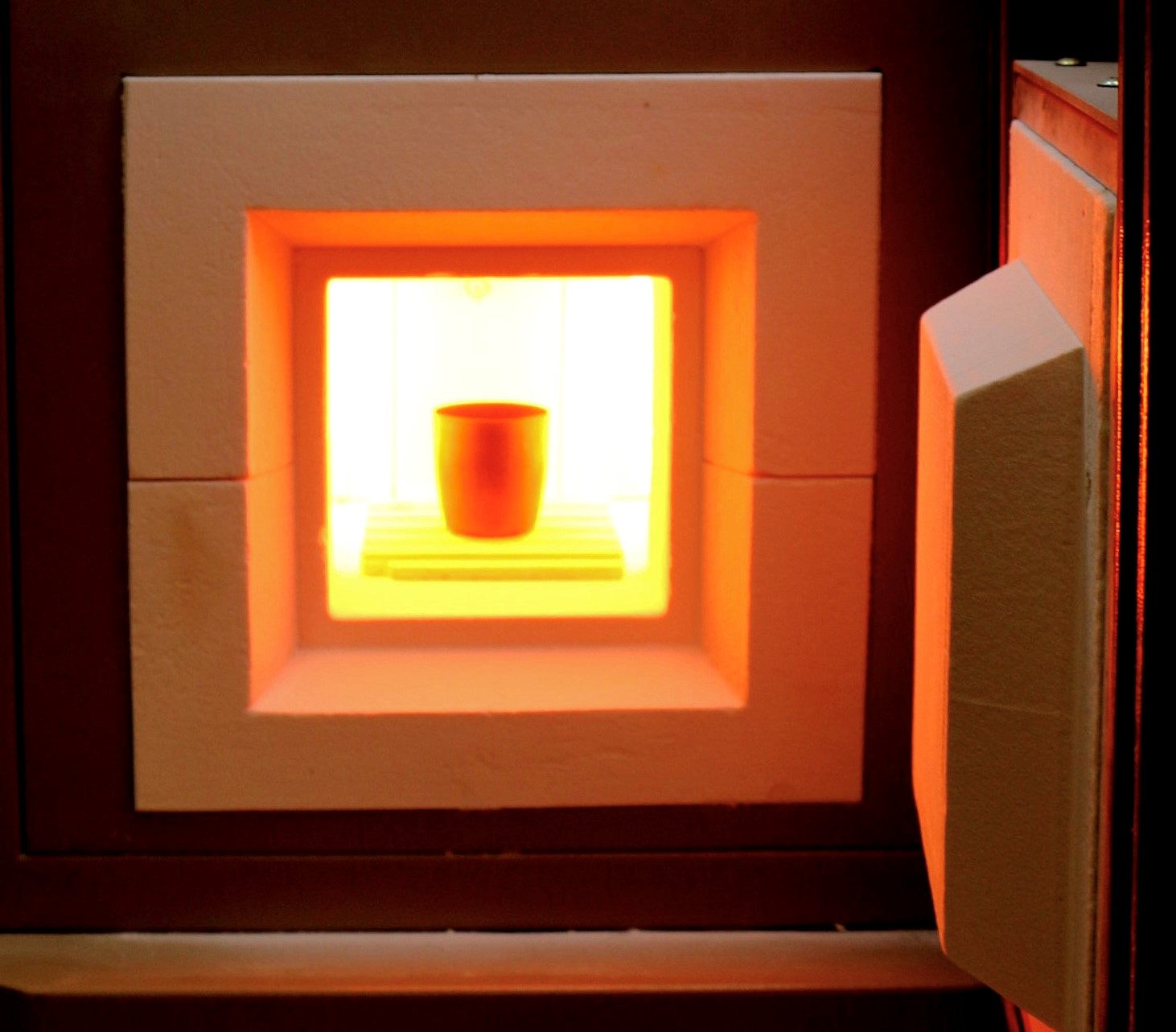

A crucible that mimics the plant melter, with contents often referred to as melter feed, is pictured inside a furnace at 2,100 degrees Fahrenheit at the 222-S Laboratory at the Hanford Site.

Cooled vitrified tank waste created at Hanford’s 222-S Laboratory will be tested to verify the quality of the glass formula and ensure it is suitable for vitrification.

Hanford tank operations contractor Washington River Protection Solutions collected samples from waste Tank AP-104 and delivered them to the lab for evaluation. Each waste tank has enough chemical differences to require a separate waste evaluation and glass formula. In the case of Tank AP-104, the tank operations contractor determined that formula and provided it to lab staff to make a laboratory-scale test of the glass formula.

In early November, Navarro-ATL scientists prepared a glass slurry by mixing glass-forming compounds with treated waste from Tank AP-104.

“The slurry was dried, turned into a powder and placed in a furnace set at 2,100 degrees Fahrenheit,” said Rob Schroeder, laboratory director at Navarro-ATL. “The high temperature melted the mixture, closely mimicking the vitrification process that will take place at Hanford’s Waste Treatment and Immobilization Plant.”

The team allowed the melted product to cool and solidify. Navarro-ATL scientists will test the cooled glass in the 222-S Laboratory to verify the quality of the glass formula and ensure it is suitable for vitrification.

To receive the latest news and updates about the Office of Environmental Management, submit your e-mail address.