Learn more about SETO’s perspective on perovskites in our Energy Focus article and our request for information on performance targets.

SETO has identified four primary challenges that must be simultaneously addressed for perovskite technologies to be commercially successful. Each challenge represents a unique set of barriers and requires specific technical and commercial targets to be achieved. The office is supporting projects working to address these challenges through several funding programs, including the SETO FY2021 Small Innovative Projects in Solar (SIPS), SETO 2020 Photovoltaics, and SETO FY20 Perovskite funding programs, as well as the Perovskite Startup Prize.

Perovskite solar cells have demonstrated competitive power conversion efficiencies (PCE) in small area devices, with potential for higher performance at scale, but their stability is limited compared to leading photovoltaic (PV) technologies. Perovskites can decompose when they react with moisture and oxygen or when they spend extended time exposed to light, heat, applied voltage, and different combinations of these stressors. To increase stability, researchers are studying degradation in both the perovskite material itself and the surrounding device layers. Improved cell durability is critical for the development of commercial perovskite solar products.

Despite significant progress in understanding the stability and degradation of perovskite solar cells, they are not currently commercially produced, primarily because of their limited operational lifetimes. Commercial applications outside the power sector may tolerate a shorter operational life, but even these would require improvements in factors such as device stability during storage. For mainstream solar power generation, technologies that cannot operate for more than two decades are unlikely to succeed, regardless of other benefits.

Early perovskite devices degraded rapidly, becoming non-functional within minutes or hours. Now, multiple research groups have demonstrated lifetimes of several months of operation. The Photovoltaic Accelerator for Commercializing Technologies (PACT), a center funded by SETO to assess, among other things, outdoor fielded lifetime of perovskite minimodules, has as of 4/22/2024 measured minimodules ~25 cm2 in size with 15-18% aperture-area PCE that had not dropped to 80% of their initial PCE after 5 months outside. See the PACT results here. For commercial, grid-level electricity production, SETO is targeting an operational lifetime of at least 20 years, and preferably more than 30 years.

The perovskite PV research and development (R&D) community is heavily focused on operational lifetime and is considering multiple approaches to understand and improve stability and degradation. Efforts include improved treatments to decrease the reactivity of the perovskite surface, alternative materials and formulations for perovskite materials, alternative contact (non-perovskite) layers and electrical contacts, advanced encapsulation materials, and approaches that counteract degradation sources during fabrication and operation.

One issue with assessing degradation in perovskites is developing consistent testing and validation methods. Research groups report performance results based on highly varied test conditions, including different encapsulation approaches, atmospheric compositions, illumination, electrical bias, and other parameters. While such varied test conditions can provide insights and valuable data, the lack of standardization makes it challenging to directly compare results and difficult to predict field performance from test results. SETO has identified, in collaboration with the perovskite PV community through a request for information (RFI), specific standardized tests for minimodules, which we believe provide essential initial targets for entities aiming to commercialize perovskite PV. These tests include International Electrotechnical Commission (IEC) 61215 standard tests evaluating UV, thermal cycling, damp heat, and potential-induced degradation, and an International Summit on Organic and Hybrid PV Stability (ISOS)-recommended test evaluating stability of devices exposed to a combination of light and heat. See the RFI results here.

Power Conversion Efficiency at Scale

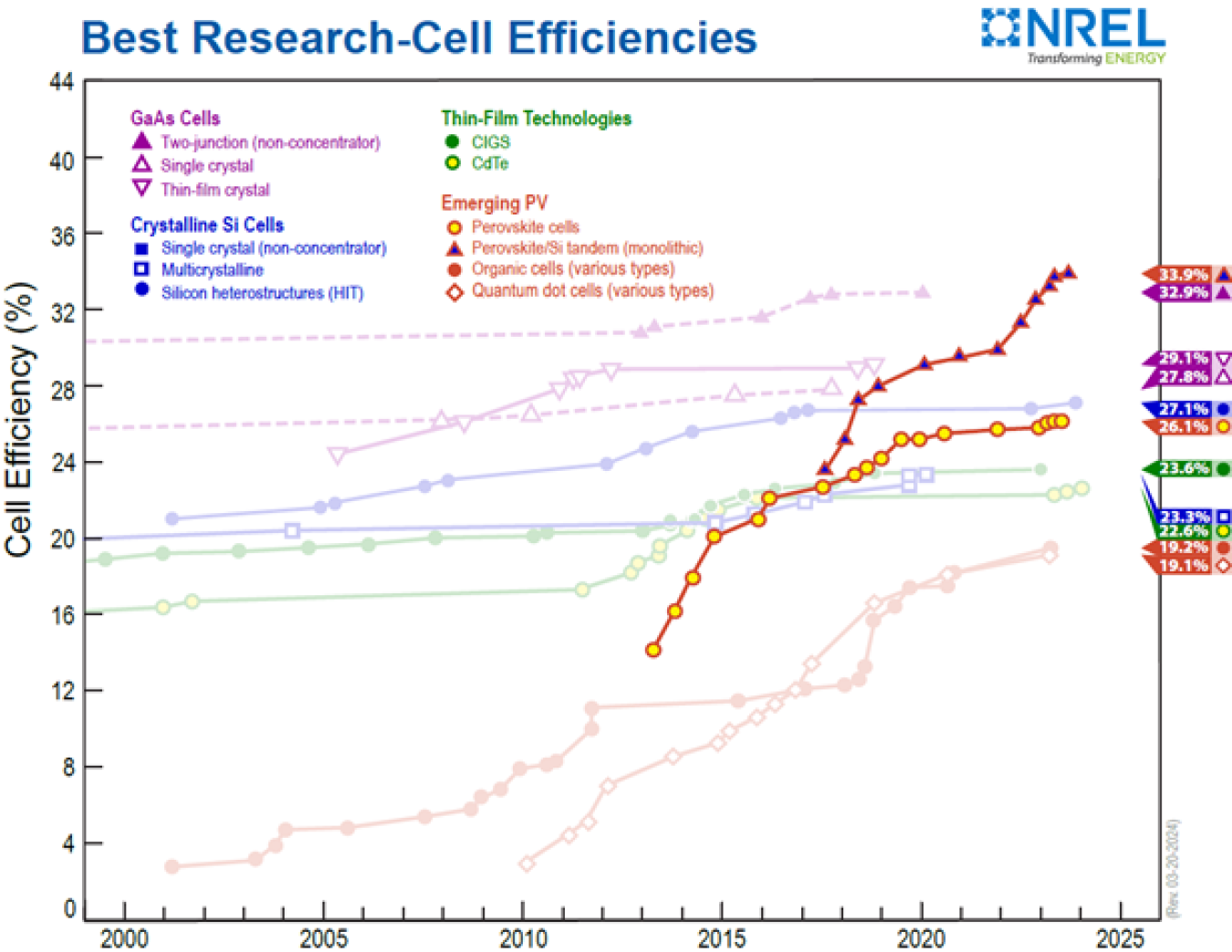

In small-area single junction lab devices, perovskite PV cells have exceeded almost all thin-film technologies (except expensive III-V technologies) in power conversion efficiency. However, high-efficiency devices have not been stable or even possible to fabricate at large scale. For widespread deployment of perovskites, maintaining these high efficiencies while achieving stability in large-area modules will be necessary.

Efficiency records for perovskite PV cells compared to other PV technologies, with current records of 26.1% for single junction perovskite devices and 33.9% for tandem perovskite-silicon devices (as of April 21, 2024).

Perovskites can be tuned to absorb different colors in the solar spectrum by changing the material composition, and a variety of formulations have demonstrated high performance. This flexibility allows perovskites to be combined with another, different absorber material to deliver more power from the same device. This is known as a tandem device architecture. Using multiple PV materials enables tandem devices to have potential power conversion efficiencies over 33%, which is the theoretical limit of a single junction PV cell in full sunlight at room temperature. Perovskite materials can be tuned to take advantage of the parts of the solar spectrum that silicon PV cells can’t use very efficiently, meaning they make excellent hybrid-tandem partners. Small area perovskite-silicon tandems have already achieved validated PCE values approaching 34%. It is also possible to combine two perovskite solar cells of different composition to produce a perovskite-perovskite tandem; however, low band gap perovskites typically incorporate tin, which reacts rapidly with oxygen, presenting additional durability challenges.

Manufacturability

Scaling up perovskite manufacturing is required to enable commercial production of perovskite solar cells. Making the processes scalable and reproducible could allow perovskite PV modules to meet or exceed SETO’s levelized cost of electricity goals for PV.

Perovskite solar cells are thin-film devices built with layers of materials, either printed or coated from liquid inks or vacuum-based deposition processed. Producing uniform, high-performance perovskite material in a large-scale manufacturing environment is difficult, which leads to a substantial difference between small-area cell efficiency and large-area module efficiency. The future of perovskite manufacturing will depend on overcoming this challenge, which remains an active area of work within the PV research community.

While the methods used to produce the best lab-scale perovskite devices are not easy to scale up, there are significant efforts to apply scalable approaches to perovskite fabrication. For thin-film technologies, these can be split into two major production types:

- Sheet-to-Sheet: Device layers are deposited on a rigid base, which typically acts as either the front or rear surface of the completed solar module. This approach is commonly used in the cadmium telluride (CdTe) thin-film industry.

- Roll-to-Roll: Device layers are deposited on a flexible base, which can then be used as either an interior or exterior portion of the completed module. Researchers have previously tried this approach for other thin-film PV technologies, but roll-to-roll processing did not gain commercial traction because of the performance limitations of these technologies and the need for additional rigid encapsulation layers to ensure multi-decadal lifetimes. However, the roll-to-roll approach is widely used to produce photographic and chemical film and paper products such as newspapers.

If high-efficiency, durable perovskite modules can be made reliably using either of these scalable fabrication approaches, they have the potential to scale rapidly because existing knowledge and supply chains could be leveraged.

Technology Validation and Bankability

Validation, performance verification, and bankability—ensuring the willingness of financial institutions to finance a project or proposal at reasonable interest rates—are essential to the commercialization of perovskite technologies. Variability in testing protocols and lack of sufficient field data have limited the ability to compare performance across perovskite devices and to develop confidence in long-term operational behavior. Additionally, the ability to replicate results at third-party validation centers is essential to validate measurements of efficiency and durability measured using in-house systems.

Current testing protocols for solar PV devices were developed for the existing mainstream PV technologies. These involve indoor testing using protocols that could also accurately predict outdoor performance in silicon and CdTe solar cells, which degrade very differently than perovskite technologies. Objective, trusted validation using test protocols that can adequately screen for real-world failure modes is critical to boost confidence in perovskite technologies, which is necessary to enable investment in production scale-up and deployment. The rapidly changing material and device compositions of perovskite solar cells make this standardized validation particularly challenging and important.

SETO has funded the Perovskite Photovoltaic Accelerator for Commercializing Technologies (PACT) Validation and Bankability Center to address these challenges. PACT is conducting field and lab testing, develop and validate accelerated test protocols and energy yield models, and conduct technical and commercial bankability studies to improve our understanding and confidence in the real-world durability of perovskite PV technologies.

SETO has also developed performance targets to support commercialization pathways for perovskite PV based on the Performance Targets for Perovskite Photovoltaic Research, Development, and Demonstration Programs Request for Information (RFI). These targets for efficiency, stability and replicability of perovskite PV devices can align research directions and goals, ensuring that future funding programs are relevant and accelerating technical and commercial development and de-risking of perovskite technologies.

Learn more about SETO’s PV research, perovskite solar cell basics, and how PV technologies work.