About Module

Module is an innovative modular housing developer, with a product that is affordable, contemporary, and energy efficient. They have developed models for townhomes, duplexes, detached single-family homes, and six-unit multifamily buildings. Each home is designed with the goal of achieving the Department of Energy’s Zero Energy Ready Home certification.

Challenge Addressed

In 2023, Module aimed to incorporate energy efficiency strategies identified in the Energy in Modular (EMOD) Buildings Method: A Guide to Energy-Efficient Design for Industrialized Construction of Modular Buildings, published by the National Renewable Energy Laboratory (NREL), into their existing modular assembly process. Integrating these strategies required workforce development to enable seamless transition to a highly efficient, low-carbon line without affecting the cost and throughput of the existing assembly line.

Technical Assistance Support Provided

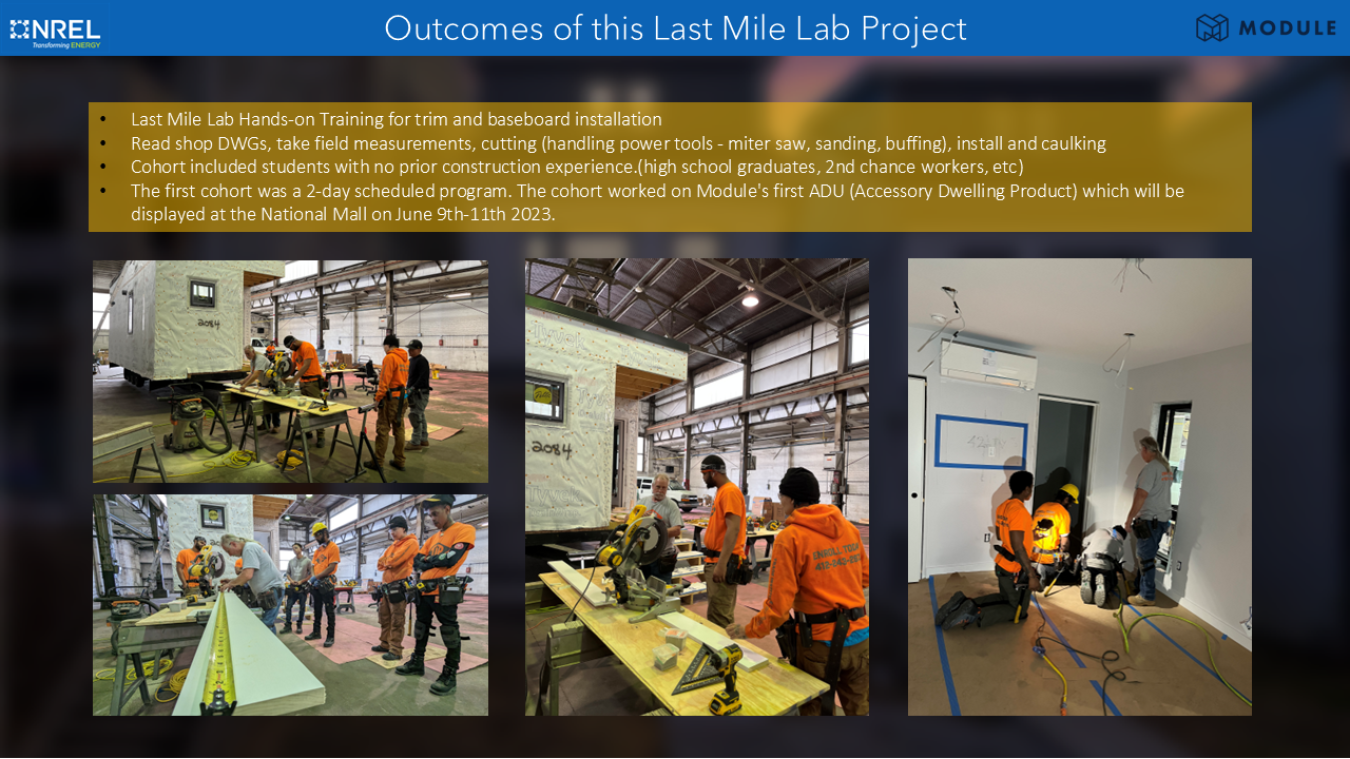

NREL assisted Module in developing the workforce training needed to streamline their ability to pursue Zero Energy Ready Home certification for their product line. With direct support from NREL and input from consultations with the Advanced Building Construction (ABC) Collaborative team, Module deployed this hands-on training at its Last Mile Facility training program.

NREL mapped its EMOD method strategies and modular net-zero design production practices to Module’s training needs at their Last Mile Innovation Lab and provided recommendations for specific training demonstrations.

The NREL technical assistance team developed an outline for Module’s workforce training needs, particularly for air barrier and envelope insulation installation. This assistance included mapping out quality assurance steps needed to verify technical installation on the factory line, including recommending that each station verify their component installations independently. NREL then introduced ways to document the sequences of tasks and building science elements for each stage of the modular assembly.

The ABC Collaborative provided additional support to Module, an ABC Collaborative member. Technology scaling support included strategic guidance and partnership building with relevant demand-side stakeholders and end users, including Habitat for Humanity and Quartz Properties; introduction to multiple venture capital firms, including VoLo Earth; and development of a value messaging framework and pitch deck. The ABC Collaborative also advised Module on specific space-conditioning strategies and materials to consider for their product lines. These developments helped Module prepare for their connection with the University of Pittsburgh Medical Center, which invested $1 million in Module to support affordable housing developments in Pittsburgh, Pennsylvania, to ease the homelessness crisis and reduce negative health effects associated with homelessness.

Comments from Module

“This was our first project with NREL and a very productive one,” said Ankur Dobriyal, Director of Off-Site Innovation at Module. “The ability of the technical assistance team to identify key parameters affecting different parts of the construction process is unparalleled. We also collaborated on identifying key assemblies that affect building performance based on NREL’s EMOD guide. It helped our team think deeply and through different approaches to tackle modular construction-specific performance and installation challenges.

“We would welcome the chance to continue collaborating with NREL, with the Last Mile Facility now up and running. Any future work and inputs will directly benefit a pipeline of affordable housing projects in disadvantaged communities. We are also working with the local trade institute on job training and employment opportunities for when the facility reaches scale. This would be the perfect opportunity for further work together.”

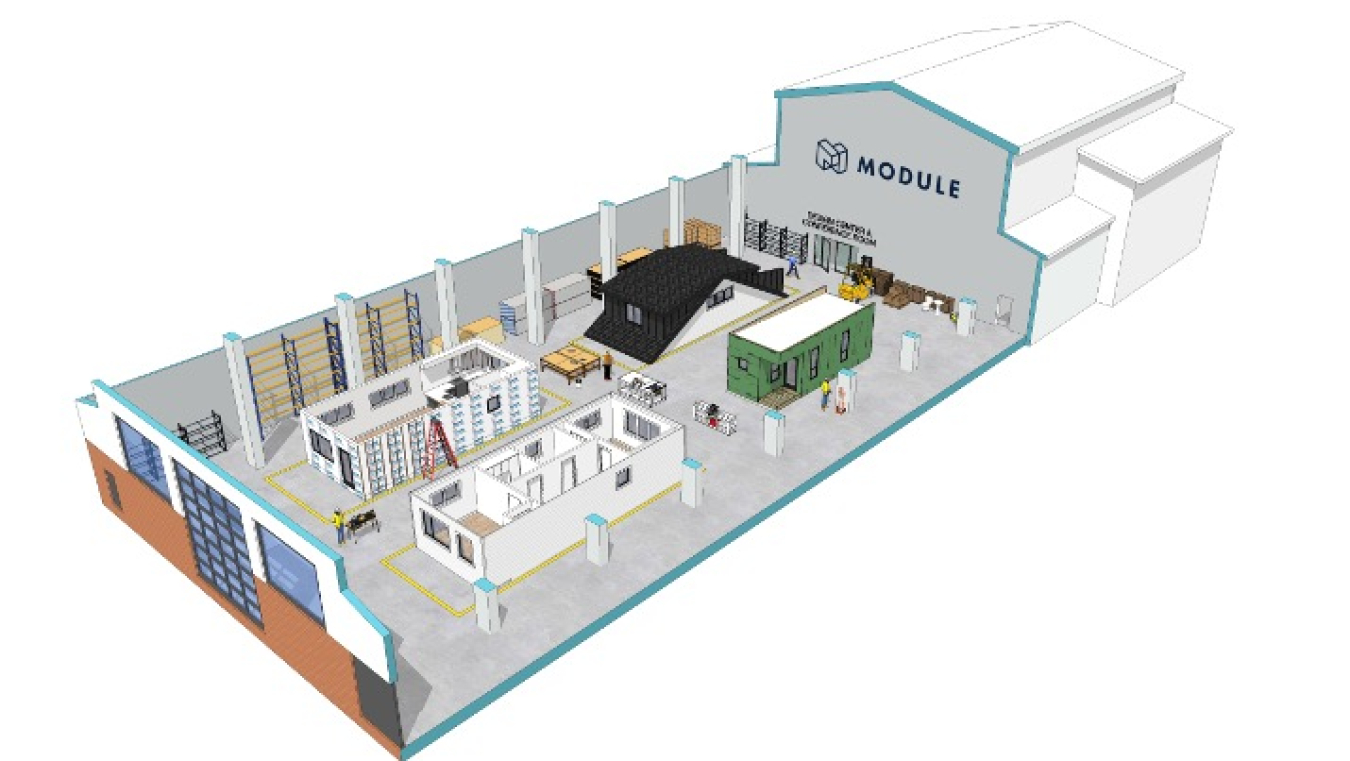

Render of Last Mile Facility Innovation Lab envisioned by Module + NREL.

The sequencing documentation for the modular assembly that NREL created will be used to develop curriculum for Module’s next phase of workforce training development.

These improvements to Module’s workforce training approach will enable the modular manufacturer to streamline compliance with Zero Energy Ready Home specifications moving forward. This work has produced collaborative action items between Module and NREL, some of which were presented at the World of Modular conference in 2024.

Technical assistance is available to help enhance the performance, productivity, energy efficiency, and carbon savings of your industrialized construction project. Contact [email protected] to learn more.

The ABC Collaborative brings together a diverse network of incumbent and emergent buildings sector actors across manufacturing, construction, real estate, development, and related areas. The Collaborative works to accelerate the uptake, scaling, and mainstream adoption of ABC while supporting—and leveraging—modernization of the U.S. construction industry.

Interested in learning more or joining? Contact the ABC Collaborative here.

About the ABC Initiative

The ABC Initiative, led by the Building Technologies Office , integrates energy efficiency and advanced technology solutions into industrialized construction processes to drastically increase the speed and scale of high-performance, low-carbon building retrofits and new construction.

.....

Page last updated: October 10, 2024