National Renewable Energy Laboratory (NREL) scientists engineered a process for making β-ketoadipic acid from lignin for $2 per kilogram, approaching cost-competitiveness with petroleum-based chemicals used for making nylon today. With support from the U.S. Department of Energy Bioenergy Technologies Office, researchers are a step closer to addressing one possible answer to the persistent question of lignin.

September 17, 2024Dr. Zia Abdullah

Dr. Zia Abdullah is laboratory program manager for the National Renewable Energy Laboratory’s (NREL’s) Bioenergy Technologies Office program.

Zia has extensive experience and accomplishments in thermochemically and biochemically converting biomass to fuels and chemicals. His experience includes more than 25 years of industrial research and development in biomass conversion, as well as problem solving, new product development, business development, and project management.

Prior to joining NREL, Zia was chief technology officer at Versa Renewables LLC, where he developed and commercialized biomass pyrolysis and biopolyol technologies. Before Versa, Zia served as one of the Battelle Memorial Institute’s 11 fellows, leading the development of technology and commercial application for fuels, chemicals, and materials from the thermochemical and biochemical conversion of biomass. Prior to working at Battelle, Zia was a research advisor (fellow) at Weyerhaeuser Company, where he worked on challenges related to manufacturing and biomass valorization.

Meet our other bloggers ►

Return to Bioprose blog ►

National Renewable Energy Laboratory (NREL) scientists engineered a process for making β-ketoadipic acid from lignin for $2 per kilogram, approaching cost-competitiveness with petroleum-based chemicals used for making nylon today.

Unlike the cellulose and hemicellulose found in plants, lignin is challenging to upgrade into biofuels or high-value bioproducts. Lignin is designed to resist decay; its interlocking molecular structure gives plants rigidity and durability. For biorefineries, the challenge in converting lignin to useful products is a century-old problem.

While lignin comprises 15%–40% of plant biomass on Earth, a pressing question has persisted as companies work to develop industrial-scale biorefining processes: What do we do with all of it?

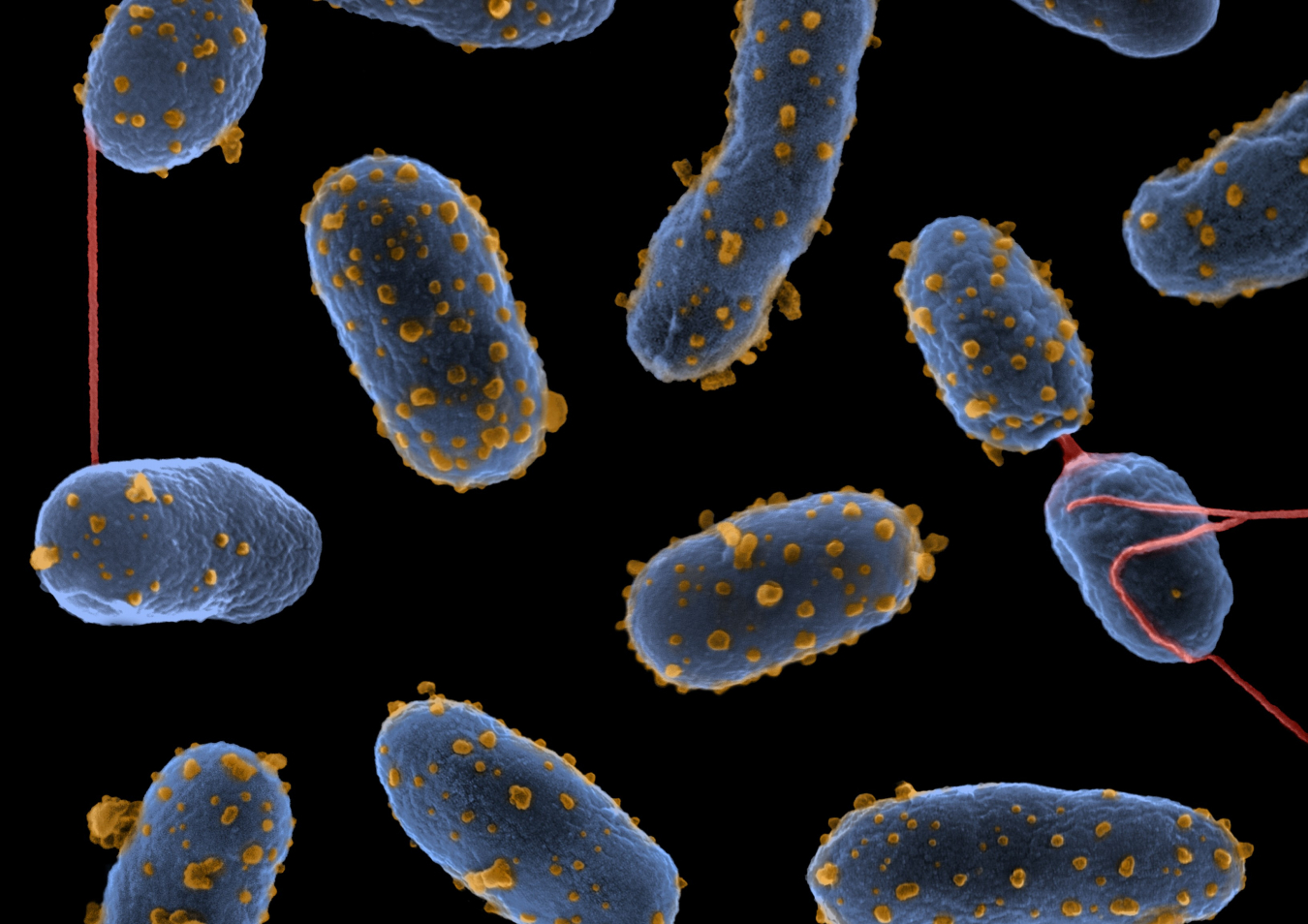

Fortunately, with the support of the U.S. Department of Energy (DOE) Bioenergy Technologies Office (BETO), researchers are a step closer to addressing one possible answer to the persistent question of lignin. In a 2023 Science Advances paper, a team of National Renewable Energy Laboratory (NREL) researchers engineered a two-step process for turning lignin from corn leaves, stalks, and cobs into a substrate that is readily converted by the bacterium Pseudomonas putida. The team engineered the bacterium to funnel the assortment of compounds in the lignin into β-ketoadipic acid—a precursor for nylon that could replace petroleum-based adipic acid used to make conventional nylon today. Analysis suggests that the precursor could be created for around $2 per kilogram—nearly the same cost to make adipic acid (historically selling for $1.10–$1.80 per kilogram). At that price, biorefineries could be better equipped to turn lignin into an important product.

So, how did the research team achieve such promising results? It boils down to three key factors.

- For Better Production Yields, NREL’s Process Feeds Bacteria Solids, Not Liquids

In previous studies, NREL fed lignin to P. putida as a liquid called an “alkaline pretreated liquor.” The dark, viscous liquid was created during a pretreatment process needed to extract part of the plant cell wall into useful aromatic compounds that are readily digestible by the bacterium. Unfortunately, the results were not optimal. The bacterium successfully digested most of the isolated aromatics, but the aromatics in the liquor were too dilute to yield large quantities of β-ketoadipic acid. In this new study, the team added an additional step to remove excess liquid and concentrate the aromatics as a dry powder. When fed the aromatics in this concentrated, powered form, P. putida produced a higher concentration of the targeted β-ketoadipic acid.

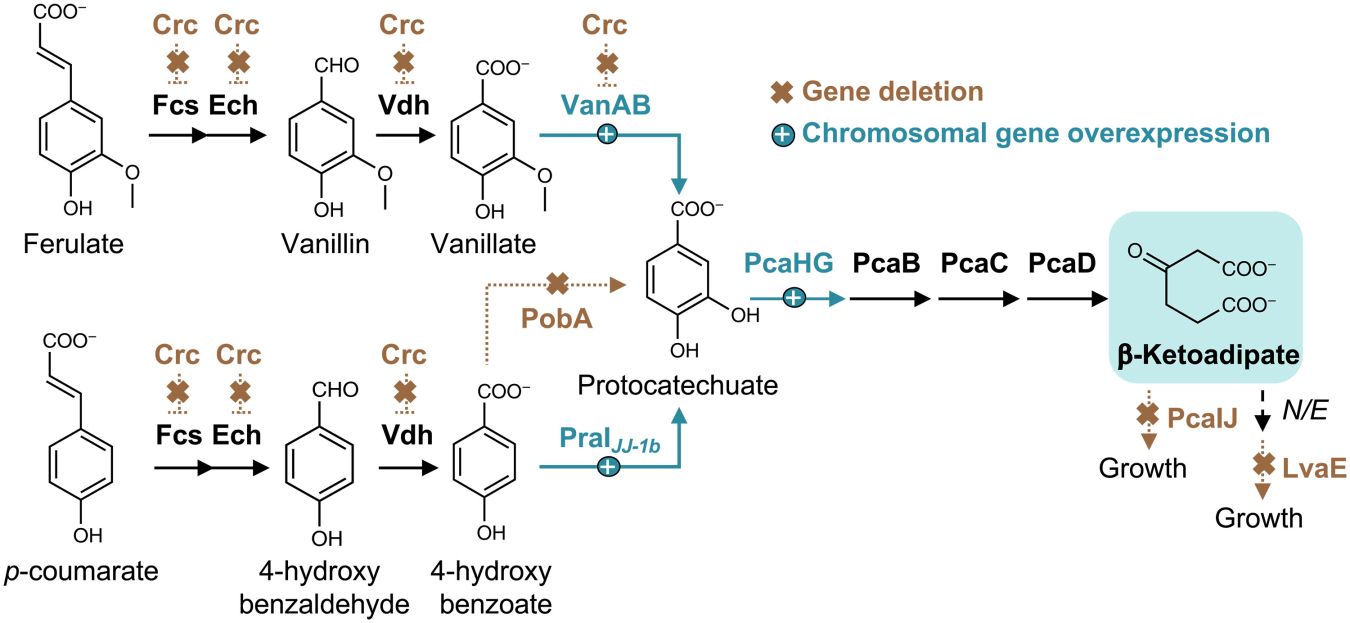

- The Bacterium’s Metabolism Is Engineered to Produce β-Ketoadipic Acid

Natively, P. putida converts aromatic compounds through β-ketoadipic acid as an intermediate for its growth. Fortunately, the bacterium is also highly tolerant of changes to those processes, which is why NREL’s team set out to engineer P. putida to produce β-ketoadipic acid as its primary product.

Building on a history of publications on the topic, the team deleted select genes and tweaked others to enable the bacterium to make β-ketoadipic acid. When the team cultivated those bacteria in a bioreactor, the results showed the bacteria together turned nearly 100% of aromatic compounds they were fed into β-ketoadipic acid.

- The Scientists Designed the Bacteria to Work Faster

For cost-effective bioprocesses, bacteria must produce the target compound quickly. When engineering the bacteria, NREL’s team prioritized reducing metabolic bottlenecks that slow the bacterium’s production of β-ketoadipic acid. After designing and comparing the performance of 10 uniquely engineered strains, the optimal strain was able to convert isolated aromatics from lignin to β-ketoadipic acid at a rate of 0.7 grams per liter per hour. Follow-up analysis showed this rate was critical for achieving cost-competitive β-ketoadipic acid production.

Putting the Question of Lignin to Rest?

Finding cost-effective, reliable methods for breaking down and valorizing lignin could greatly improve biorefinery economics. Indeed, some estimates show potential to lower the cost of making sustainable aviation fuel by as much as $4 per gasoline gallon equivalent just by adding an effective method for converting lignin into valuable byproducts.

Taken together, these improvements show promise for enabling biorefineries to do just that. According to the team’s analysis, a future facility using the process could sell β-ketoadipic acid made from lignin for $2.01/kg.

NREL’s promising approach turns lignin leftover from biofuel production into a valuable and more sustainable product—something companies can sell to boost total biorefinery income. That could put us one step closer to putting the pressing question of lignin to rest once and for all.

Dr. Zia Abdullah is laboratory program manager for the National Renewable Energy Laboratory’s (NREL’s) Bioenergy Technologies Office program.