Preventing clothes from shedding may be impractical, if not impossible. However, scientists from the U.S. Department of Energy’s (DOE) Bio-Optimized Technologies to keep Thermoplastics out of Landfills and the Environment (BOTTLE™) consortium have developed an emerging solution that could address the challenge at its source: replace today’s petroleum-derived polyester with a nontoxic, biodegradable alternative made from PHAs, short for “polyhydroxyalkanoates.”

March 21, 2024

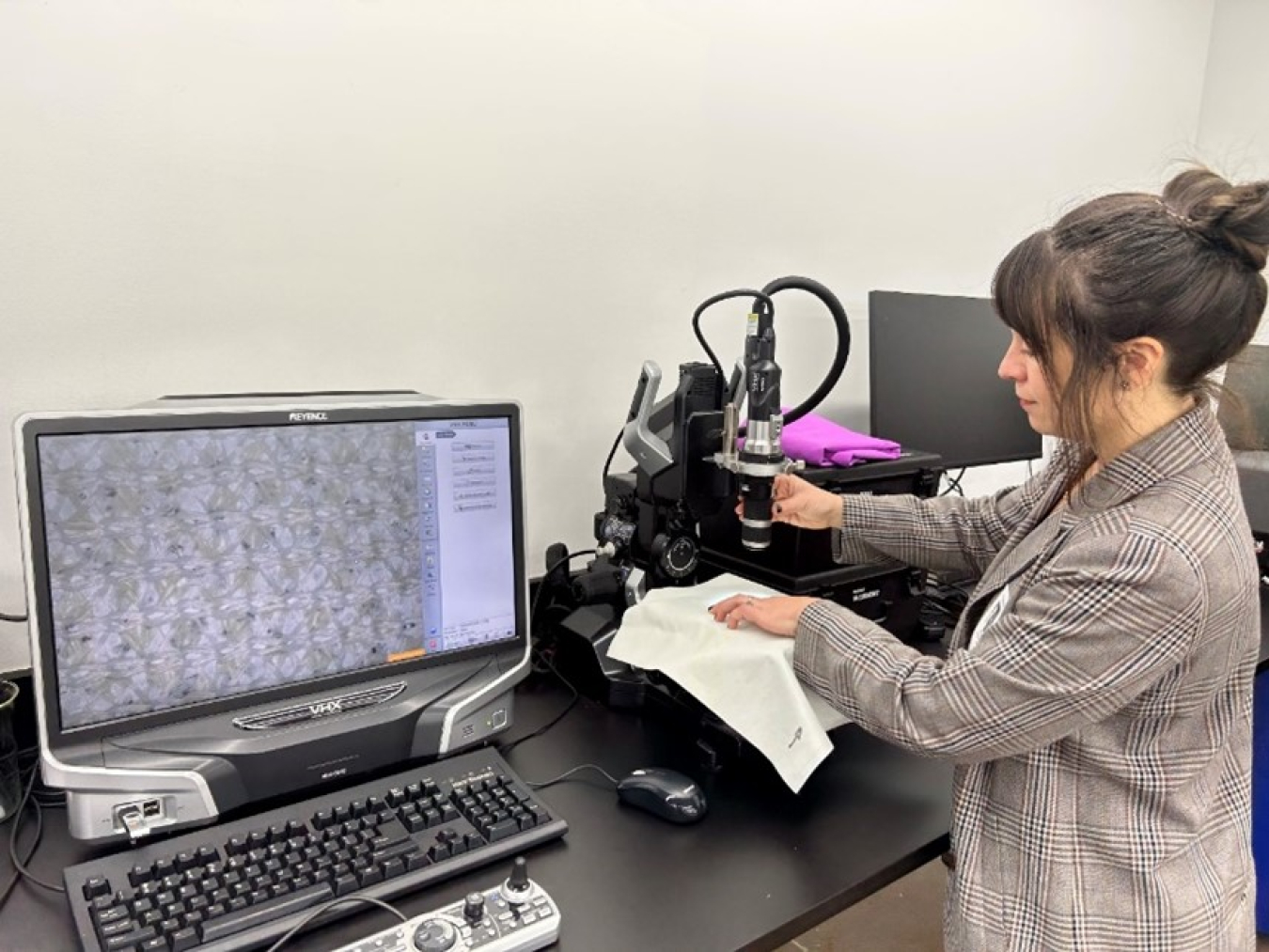

NREL Scientist Kat Knauer examines a weave of a novel bio-based textile using optical microscopy at The North Face’s Denver, Colorado, laboratories. Photo by Julie Thompson, The North Face.

When worn, washed and dried, clothing can shed and disperse tiny fibers throughout homes, soils, and waterways. These fibers, often made of polyester and often too small to see, are a major—if invisible—source of microplastic pollution that take centuries to degrade and that exacerbates a growing environmental and public health hazard.

Preventing clothes from shedding may be impractical, if not impossible. However, scientists from the U.S. Department of Energy’s (DOE) Bio-Optimized Technologies to keep Thermoplastics out of Landfills and the Environment (BOTTLE™) consortium have developed an emerging solution that could address the challenge at its source: replace today’s petroleum-derived polyester with a nontoxic, biodegradable alternative made from PHAs, short for “polyhydroxyalkanoates.”

Scientists from the DOE Bioenergy Technologies Office (BETO) and Advanced Materials & Manufacturing Technologies Office -funded BOTTLE —including a team from the National Renewable Energy Laboratory and Colorado State University—have developed a portfolio of PHAs with different properties in the lab, including some that behave like conventional polyester but are bio-based, biodegradable, and easier to recycle.

Now, in conjunction with The North Face, that team is bringing those sustainable materials into the outdoor apparel industry. Over the next 12 months, BOTTLE will scale the process to produce several pounds of PHA fiber, which The North Face will test and evaluate for use in its product lines.

Read more about this emerging plastics research and the industry partnership working to bring sustainable textiles to the market.