Lead Performer: Rensselaer Polytechnic Institute – Troy, NY

February 14, 2024

Lead Performer: Rensselaer Polytechnic Institute – Troy, NY

Partners:

-- Hempitecture – Ketchum, ID

-- Introba – St. Louis, MO

-- Durasip – Fort Worth, TX

DOE Total Funding: $1,499,962

Cost Share: $406,067

Project Term: January 1, 2024 – December 31, 2026

Funding Type: Buildings Energy Efficiency Frontiers & Innovation Technologies (BENEFIT) – 2022/23

Project Objective

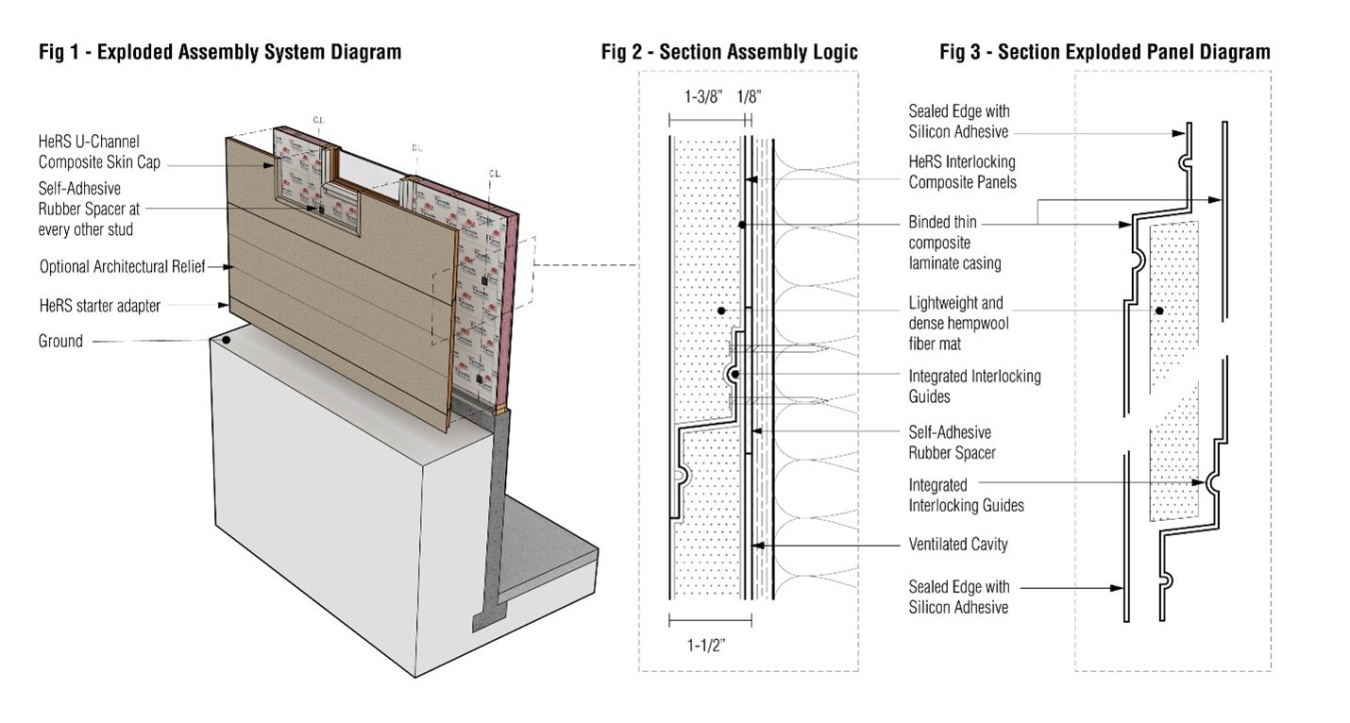

Hemp Retrofit Sips (HeRS) is a low-embodied carbon, hemp-based insulated cladding system for buildings. The project goal is to develop, and validate in the field, a commercially viable, logistically simple, and durable building retrofit technology manufactured from natural fibers that can provide 15-25% HVAC energy savings when applied to residential buildings constructed with obsolete building codes. With expertise in architectural design, supply chain risk management, material and building science, bio-composite manufacturing and marketing, and whole building energy simulation, the project team is well-equipped to successfully achieve this goal. We will develop an insulated siding system primarily made of hemp fiber for both the core and skin materials, with a form factor similar to existing siding products, and at a cost premium of $1/ft2 over the $3-7/ft2 industry standard cost of a siding system installed. Our performance targets include simplified logistics for installation, a total thickness of the system installed of < 1½”, and an R value of > 5. Crucially, and specific to our project, is the demonstration of a significantly reduced embodied carbon footprint for our system when compared to other similar synthetic material products. Furthermore, our aim is to conduct a viability study for supply chains that will demonstrate how quantities of hemp fiber produced in the United States can be effectively integrated into the production line of HeRs. This will serve to highlight the significance of a project of this nature in terms of creating job opportunities across the agriculture, processing, manufacturing, and construction sectors in the United States.

Rensselaer Polytechnic Institute (RPI), represented in this project by its Center for Architecture, Science, and Ecology, has created a strong interdisciplinary RD&D team comprised of Hempitecture, a leading hemp fiber insulation materials company; Durasip, a manufacturer of fiber reinforced skins with significant production flexibility; Introba, a global architecture and engineering firm that specializes in advanced building systems integration; and RPI faculty members representing the Architecture, Materials Science, Mechanical Engineering, and Business departments.

Project Impact

Residential buildings account for 60% of the total built surface area of the United States, with over two-thirds being single-family homes. Over half of these homes were constructed prior to 1980, when energy-efficiency standards were less strict. Although significant progress has been made in using renewable energy and improved building design to reduce building operational carbon, little progress has been made in decreasing embodied carbon, the carbon emitted during the manufacturing of building materials and construction processes. A recent UN Environmental Global Status Report estimated that by 2040, 57% of total CO2 emissions from the building industry will be attributed to embodied carbon. The HeRS helps reduce the operational carbon of a significant portion of the building stock in the United States by making a cost-effective and easy-to-install building envelope retrofit technology. Additionally, it addresses the embodied carbon of such an effort by utilizing a highly efficient, carbon-sequestering crop (HEMP) as its primary source of material. At a broader scale, HeRS, which relies on the local harvesting and processing of hemp fiber, has the potential to create incentives for farmers to grow hemp and for local communities to establish processing facilities for the extraction of fibers and herd from the raw plant. As the demand for hemp-derived products continues to rise, so will the need for skilled labor in areas such as farming, processing, and manufacturing. This presents a unique opportunity for the establishment of local, biomaterial economies, allowing for underrepresented communities to gain access to well-paying jobs and build careers in multiple sectors of this industry.

Contacts

DOE Technology Manager: Sven Mumme

Lead Performer: Alexandros Tsamis, Rensselaer Polytechnic Institute