The training team at the Hanford Site’s Waste Treatment and Immobilization Plant (WTP) recently added an extra level of realism to employee trainings by upgrading classrooms and adding new props.

Office of Environmental Management

January 16, 2024

Waste Treatment Completion Company Radiological Control Training Instructor Chris Oliveros poses inside a new radiological control training classroom at the Hanford Site’s Waste Treatment and Immobilization Plant.

RICHLAND, Wash. — The training team at the Hanford Site’s Waste Treatment and Immobilization Plant (WTP) recently added an extra level of realism to employee trainings by upgrading classrooms and adding new props.

The improvements are intended to build operational readiness by allowing students to train in scenarios that closely resemble what they will encounter on the job.

Mat Irwin, EM Office of River Protection acting assistant manager for the Waste Treatment and Immobilization Plant Project, believes the changes will be beneficial.

“These improvements bridge the gap between training and practical application. When the students encounter situations like what they’ve practiced, they’ll be better equipped to handle them,” he said.

The WTP radiological worker training program now features a classroom set up to simulate working in a radiological environment. Students are required to wear protective gear, just as they would in the field. The classroom also includes a dedicated space for students to practice putting on and removing personal protective equipment.

“We've intensified the challenges, mirroring the intricacies of accessing radiologically controlled areas,” said Owen Peters, training and procedures manager for Waste Treatment Completion Company, a subcontractor to WTP lead contractor Bechtel National, Inc. “We've even introduced fluorescent materials to demonstrate how contamination spreads in the absence of proper radiological practices."

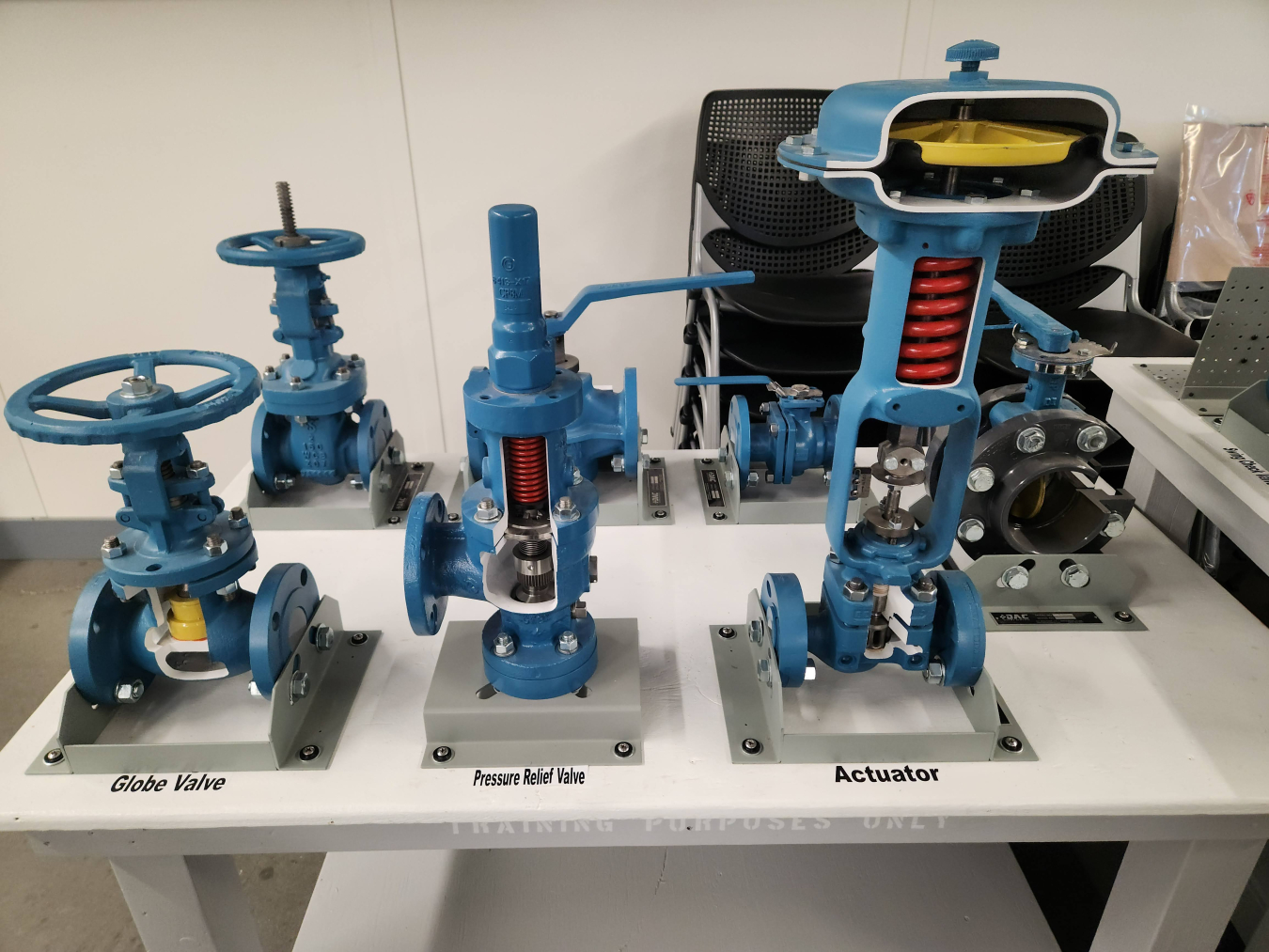

By cutting away parts of valves, the Waste Treatment and Immobilization Plant’s new training props show students the inner workings of valve systems.

Elsewhere on the WTP jobsite, a new set of training props are helping students gain a better understanding of valve systems. Fourteen different types of valves have had pieces cut away to reveal their inner mechanisms.

“These cutaway props allow students to enhance their understanding of valve systems and apply that to their work," said Sara Hannickel, operations training supervisor for Waste Treatment Completion Company. “The hands-on training is contributing to fewer errors in the field and providing an all-around better learning experience."

-Contributor: Tyler Oates

To receive the latest news and updates about the Office of Environment Management, submit your e-mail address.