Step 9 of the site-level federal fleet electrification process is to coordinate fleet location electrification efforts with the local utility service.

Navigate the ZEV Ready Process

| Design Phase Steps |

|---|

| 8. Engage with key electrification stakeholders at site |

| 9. Coordinate with local utility service |

| 10. Complete site assessment and design EVSE |

| 11. Identify EVSE at non-agency locations |

| 12. Work with leadership to secure EVSE funding |

Return to the ZEV Ready Center to see all 15 steps.

Primary Audiences

|

Site ZEV Champions |

|

Site Location Fleet Managers |

|

Facility Infrastructure Managers and Utility Staff |

|

Facility Energy Managers |

Successful electrification requires strong communication and collaboration across many of the key fleet electrification stakeholders at the site location. In addition to the site location fleet managers, facility infrastructure managers, and facility energy manager, the site ZEV champion should manage the coordination of fleet location electrification efforts with the local utility service.

Coordination with local utilities early in the process is recommended to ensure effective electric vehicle supply equipment (EVSE) design and deployment and to identify opportunities to use financial and/or design support programs offered by utilities. Utility upgrades can significantly delay the EVSE installation timeline; it is critical to engage utilities early in the process.

Utility Finder

Agencies can use the Utility Finder (U-Finder) tool to help identify local utility partners, EV and EVSE programs and incentives, and Clean Cities Coalitions using the ZIP Code of each of their facilities.

Overview: Coordinate with Local Utility Service

The site ZEV champion, in coordination with the site location fleet managers, facility infrastructure managers, facility energy managers and staff, and other key stakeholders at the fleet location, should make efforts to contact their local electric utility representative early in the EVSE site design process. Installing EVSE, as with the addition of any large electrical load, may impact power needs at the facility, and require the consideration of possible equipment upgrades. Working with the utility will help the fleet location understand the electrical equipment and rate schedule cost impacts prior to deciding on the EVSE design and deployment, as well as ensuring that—when the EVSE is deployed—the utility supply equipment will be adequate for handling the increased electrical load.

Evaluating EVSE Impacts on Electric Service Equipment

Deploying EVSE may exceed the power limitations of current electrical service equipment such as service panels, wires, and transformers. The first step in understanding these impacts is to perform an energy audit to determine the nature of a facility's existing loads and the remaining equipment capacity.

Following this, consideration of both facility and utility-owned equipment is necessary to determine the remaining capacity after the installation of EVSE and predict any equipment upgrades that may be needed.

It is important to note that the NEC requires that continuous loads such as EVSE be protected at 125 percent of their rated capacity (e.g., 32-A EVSE requires a 40-A circuit breaker). Consider whether certain locations have more excess power capacity to minimize installation costs.

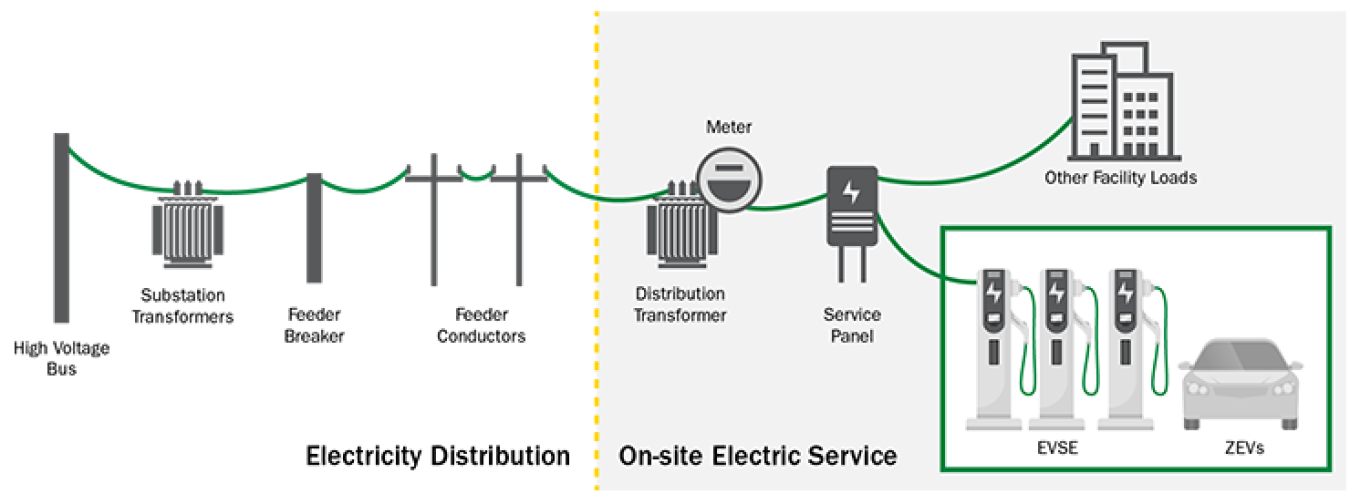

The first step in determining the role of the utility and facility in modifying electric service equipment to handle EVSE impacts is to determine equipment ownership. Figure 1 below outlines a typical electric distribution system, including facility equipment and EVSE. Discussions between the facility infrastructure manager and local utility representative will better inform where the ownership divide exists. However, in almost all circumstances, the facility will own and operate equipment to the right of the meter (see Figure 1). As building loads and overall facility size increases, this line of ownership tends to shift more to the left, leaving the facility responsible for a wider scope of equipment.

Figure 1. A typical electric distribution system, including facility equipment and EVSE.

Figure 1. A typical electric distribution system, including facility equipment and EVSE.The ownership divide line is important because everything the facility owns and maintains must be updated and completely paid for by the facility. These upgrades will most often include increased service drop—the wire between either the feeder conductors or distribution transformers and the meter or load center—or distribution transformer capacity. However, these upgrades should only be necessary if an additional service panel or larger main circuit breaker are installed. For the rest of the situations where upgrades may be required on electric utility owned equipment, the responsibility of installing and paying for these upgrades will be different depending on local utility practices.

Evaluating EVSE Impacts on Power Requirements

The scale of EVSE power requirements is determined by charging speed and the number of charging ports. For example, a single 250-kW Extreme Fast Charger can provide 100 miles of charge in 6 minutes with the same power capacity requirements as 179 Level 1 EVSE ports and 35 AC Level 2 EVSE ports, as shown in Table 1.

Table 1. EVSE Power Requirements

| Charger Type |

Extreme Fast Charger |

DC Fast Charger |

AC Level 2 |

AC Level 1 |

|---|---|---|---|---|

|

Power Level |

250 kW |

50 kW |

7.2 kW |

1.4 kW |

|

Time to Charge |

0.1 hours |

0.6 hours |

3.9 hours |

20.1 hours |

|

Equivalent Number of Chargers Installed at 250 kW |

1 port |

5 ports |

35 ports |

179 ports |

*Time to charge 100 miles is based on 3.6 miles/kWh, a sales weighted average calculated using data from Argonne National Laboratory (2019). Time to charge larger ZEVs, such as pickup trucks, are longer since they typically have lower miles per kWh.

Therefore, it is worth considering what power level is truly appropriate for the use case. Rather than oversizing service equipment to meet an unlikely future scenario, it is appropriate to base EVSE power levels and upstream electrical service needs on the use case of existing vehicle driving patterns as they would function if transitioned to electric vehicles (EVs). In a simple use case, if a vehicle never drives more than 50 miles in a day on gasoline and always parks overnight, a Level 1 charger may suffice for overnight charging. Level 1 EVSE also may be preferred for plug-in hybrid electric vehicles (PHEVs), with typical 25 to 50 mile electric ranges. For fleet applications, 250-kW Extreme Fast Chargers provide similar refueling times to gas stations, which average roughly 8 minutes per station plus 12 minutes driving off-course for fleets (Geotab 2020).

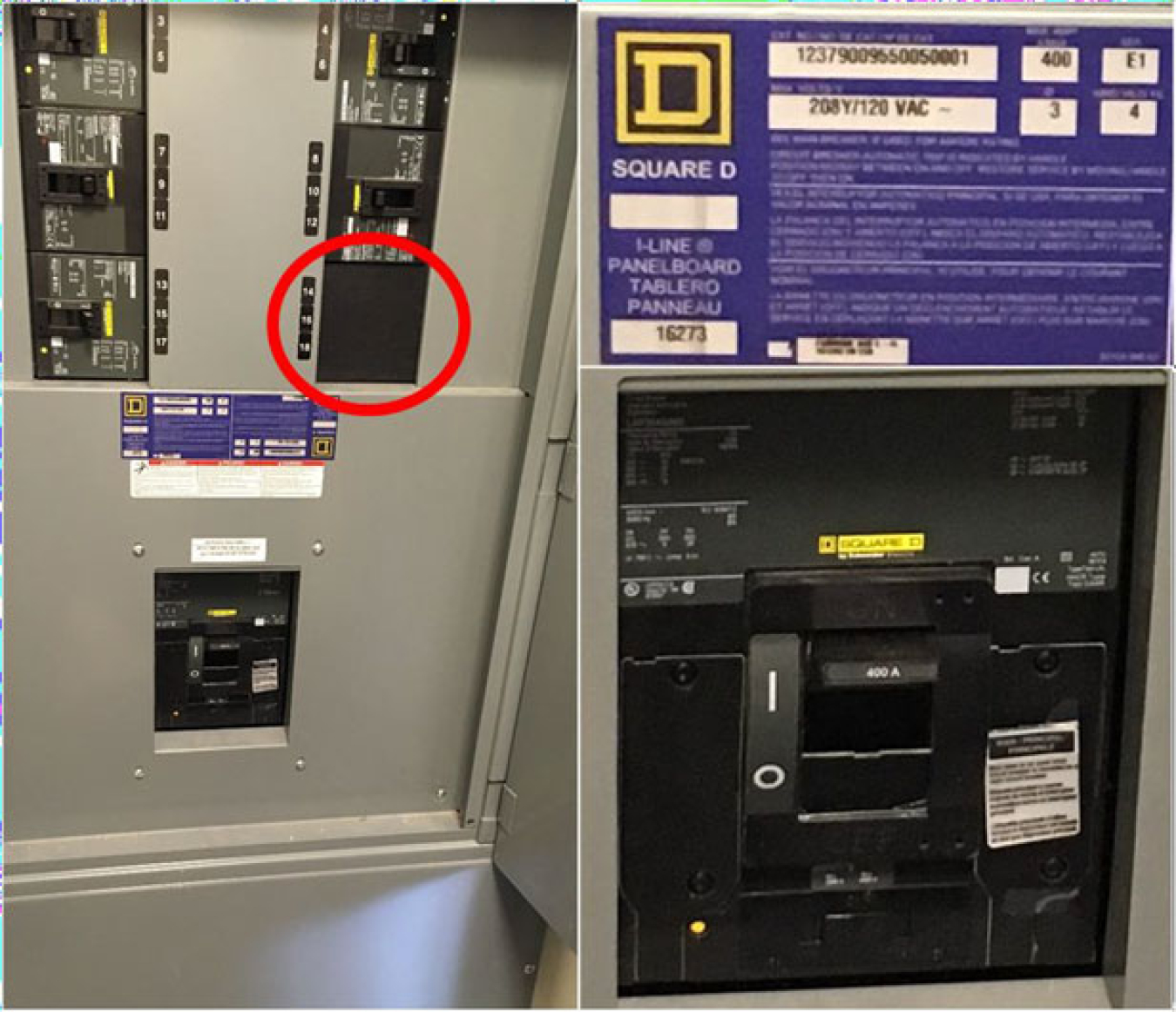

Figure 2. A main distribution panel with an open breaker position (red oval), a 400-A 208-Y enclosure rating, and a three-phase 400-A main breaker, indicating 144 kW of three-phase power capacity.

Every piece of electrical service equipment (EVSE, service conductors, circuit breakers, service panels, meters, transformers, feeder lines, etc.) is rated for an appropriate power level. If exceeded, that equipment will fail and may become unsafe. Therefore, it is critical to assess each element in the chain, at least up through the service transformer, which is typically protected by a main distribution panel.

The main distribution panel shown in Figure 2 has an open breaker position (red oval) where an appropriately sized circuit breaker could be installed, a 400-A 208-Y enclosure rating, and a three-phase 400-A main breaker, indicating 144 kW of three-phase power capacity. For context, this panel is served by a 150-kVA transformer.

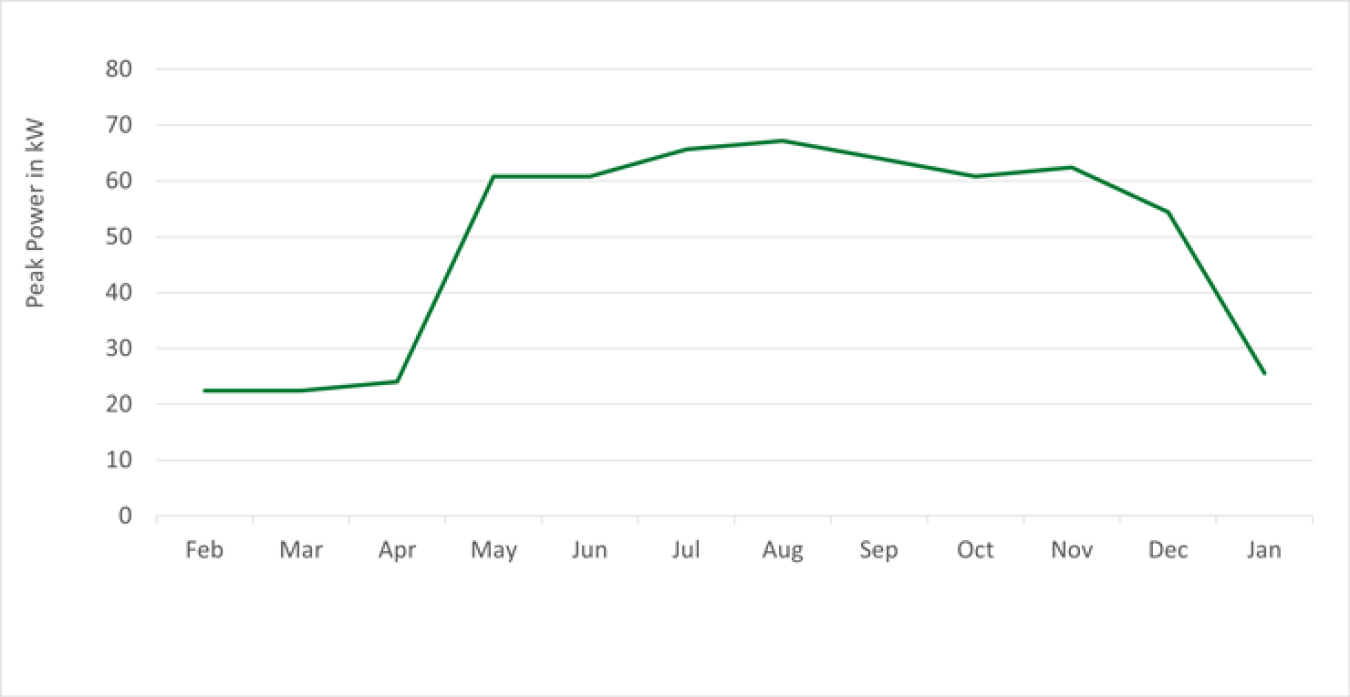

Electrical loads are sometimes measured (such as with a demand meter) and sometimes must be estimated. Energy management information systems often store power load data over time, which is useful when assessing the inconsistent nature of these loads and sizing equipment correctly. Figure 3 shows the maximum monthly peak demand for the main distribution panel (shown in the Power Capacity section above), indicating that no more than 67 kW is ever required at this location. Therefore, 77 kW of capacity is available from the service panel out of the total 144 kW of capacity. Even more capacity may be available if the facility limits ZEV charging when facility demand is low (managed charging) rather than during peak demand.

Figure 3. Maximum monthly peak demand for the main distribution panel indicates that no more than 67 kW is ever required at this location and 77 kW of capacity is available from the service panel out of the 144 kW of total capacity.

This information allows an EVSE site assessment team to determine how many EVSE ports at a particular power level could draw power from this panel. In the example shown in the Power Capacity section above, nine Level 2 EVSE at 208 V (6.7 kW each) could be installed (after accounting for NEC requirements to oversize protective equipment for continuous loads). This may be sufficient for a relatively small transportation motor pool, but a managed charging solution or a new main distribution panel and transformer may be necessary for larger numbers of EVSE or higher power equipment.

It is important to also assess the effect of EVSE load on the overall electricity demand and consumption at a federal location or facility. The major issue with adding EVSE load is the impact on peak demand, and the capacity of the current electric service to support that demand.

As an example, a federal facility with an on-peak maximum demand of 54,379 kW decides to install EVSE to support electrification of its fleet. The fleet at the facility locations includes 682 light-duty vehicles and 648 medium- or heavy-duty vehicles. If the fleet transitioned all of those vehicles to electric and, during the existing peak, 50 percent of those vehicles were charging on Level 2 chargers simultaneously, they would increase the maximum power demand by 4,459 kW or 8 percent. This could require new feeder lines and upgrades to substations (managed by either the facility or the utility) as well as result in substantially increased demand charges on the utility bill.

Issues at a facility-level tend to become more significant for larger vehicles and BEVs because they require higher power EVSE. For example, buses sometimes use 65-kW DCFC for depot charging, requiring approximately 10 times more power than Level 2 EVSE. Therefore, controlling bus loads is more significant for demand charges and system upgrades than cars and SUVs on a vehicle-by-vehicle basis. Distributing EVSE across the facility reduces the demand on low voltage transformers.

Utility Equipment Upgrades

All EVSE require the installation of new circuit breakers and wiring from the service panel to the EVSE. However, when installing a large number of EVSE, such as five or more at one location, additional upgrades are often required. Site fleet managers should coordinate with facility infrastructure managers and the local utility service (where appropriate) to determine which equipment is at risk of becoming overloaded. This will require the consideration of existing loads, as informed by the energy audit, in conjunction with anticipated EV charging loads. This will generally include service panel and main breaker ratings that could be overloaded during a coincident peak of facility and EV charging loads.

The best planning practices to address equipment considerations tend to vary based on the characteristics at each location. However, there are some general rules that will apply in most situations.

Plan for the future—If additional EVSE will be needed in the future, it is best to include those future loads in equipment capacity considerations. This will be most relevant when a service panel upgrade, a new transformer, or a distribution feeder line is required. When installing new equipment such as a service panel, it is best to account for the extra capacity needs of future EVSE.

Scale back when practical—There may be situations where the EVSE plans for a particular site are just barely exceeding the capacity limitations of the service equipment. In these circumstances, it could be most practical to slightly reduce the near-term plans for EVSE by delaying current equipment upgrades and expediting the construction process to install new equipment to support both near-term and medium-term EVSE installation.

Use managed charging—The site can mitigate peak demand impacts by using managed charging to avoid EVSE operation during peak demand times.

Becoming ZEV Ready

As part of the Charging Ready component of the ZEV Ready certification, the site ZEV champion, together with the site location fleet manager, facility infrastructure manager, and facility energy manager, should coordinate with the local utility service early in the EVSE design process to complete an energy audit and determine if planned EVSE many impact power needs at the facility and require the consideration of possible equipment upgrades.

| PHASE | ZEV READY | STEP | ACTIONS |

|---|---|---|---|

|

DESIGN |

|

9. Coordinate with local utility service |

✔ The site ZEV champion along with the site location fleet manger, facility infrastructure manger, and facility energy manager should coordinate with the local utility service, including determining if additional power is required and whether the utility offers incentives or technical support. ✔ The site facility infrastructure and energy manager should complete an energy audit to determine the EVSE power requirements and impacts at the facility level and point of interconnection. |