DOE Office of Science report examines challenges and mitigations for research facilities

June 2, 2022

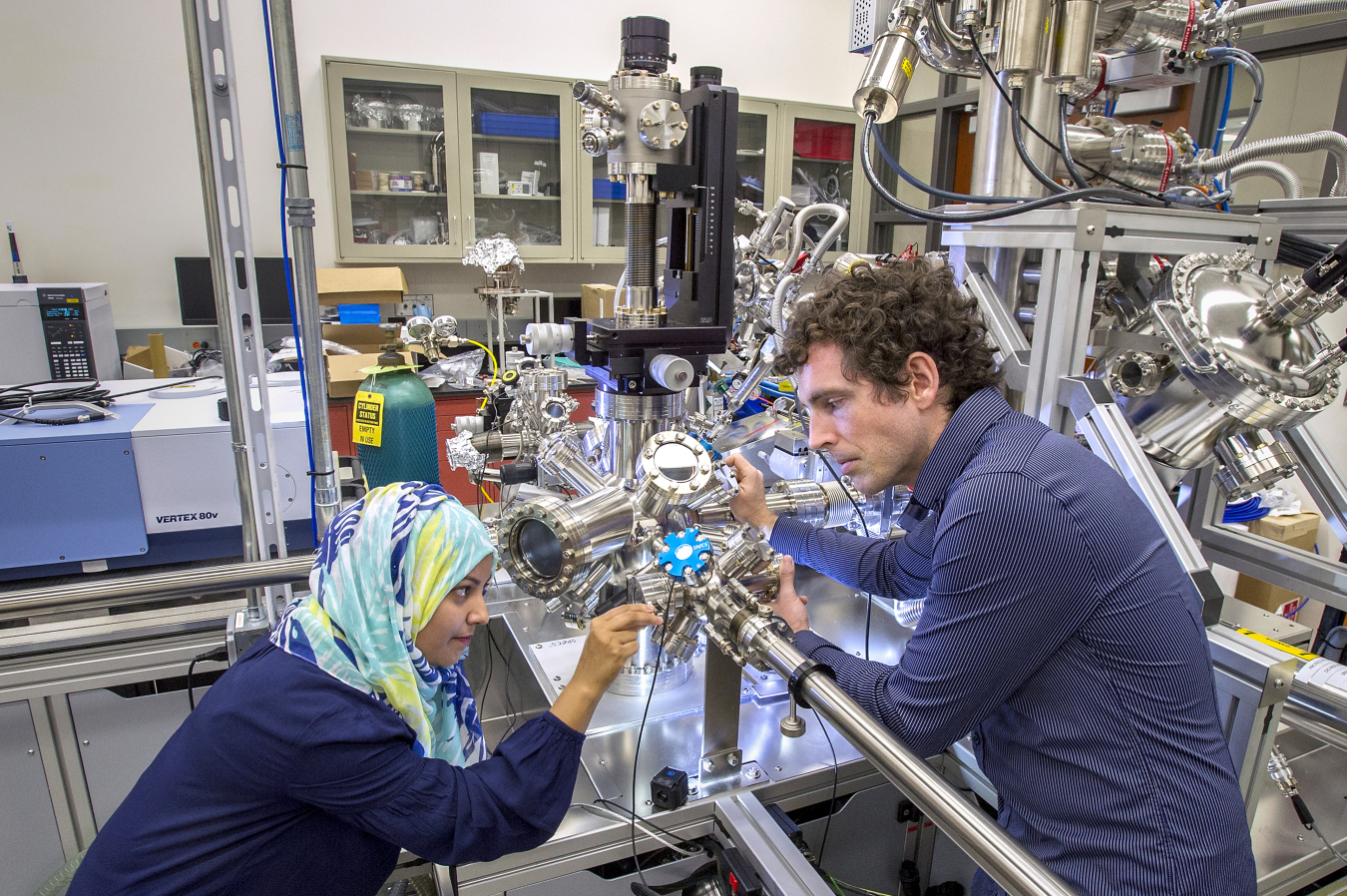

Scientists often use unique materials and specialized equipment for research—such as powerful accelerators to move nuclei at half the speed of light or electron microscopes to probe individual atoms. At the U.S. Department of Energy (DOE) Office of Science (SC), our national laboratories and user facilities house tools that are often at the forefront of technology and are frequently one-of-a-kind instruments.

These tools contain many thousands of unique components and take months or years to build. That’s why global supply chain disruptions—such as delayed shipping, high demand, or skilled labor shortages—can impact research. However, a mitigation plan can help keep projects on track.

In November 2021, SC held a roundtable on “Supply Chain Risk Mitigation for Scientific Facilities and Tools.” Our roundtable coincided with two Executive Orders issued by President Biden that aim to strengthen America’s supply chains and U.S. competitiveness, including EO 14017, “America’s Supply Chains.” This executive order directs agencies like DOE to review their supply chain challenges.

The SC roundtable gathered information about challenges relevant to our science mission. We called on technical, project management, and procurement experts from DOE national laboratories, industry, academia, and other government agencies. Panelists explored opportunities, possible partnerships, and mechanisms to strengthen the domestic supply chain for important scientific technologies. This month, we issued a report of our findings.

In the roundtable report, panelists identify common supply chain issues across SC national laboratories and user facilities. In some cases, there may be few vendors to choose from. In others, labs may have difficulty attracting vendors to produce limited quantities of high-risk or highly specialized components. High demand may lead to long delivery times or lower quality work. Vendors may also find it difficult to connect with labs and learn the current or future needs of scientific projects.

The report describes example materials, components, and systems that are at risk or could be at risk of supply chain strains. For instance, the element niobium is mostly used for high-grade structural steels and commercial applications like medical MRI machines. SC labs need specially processed, high-purity niobium for superconducting technologies in particle accelerators, detectors, and other instruments. Yet, there is no domestic producer for high-purity niobium.

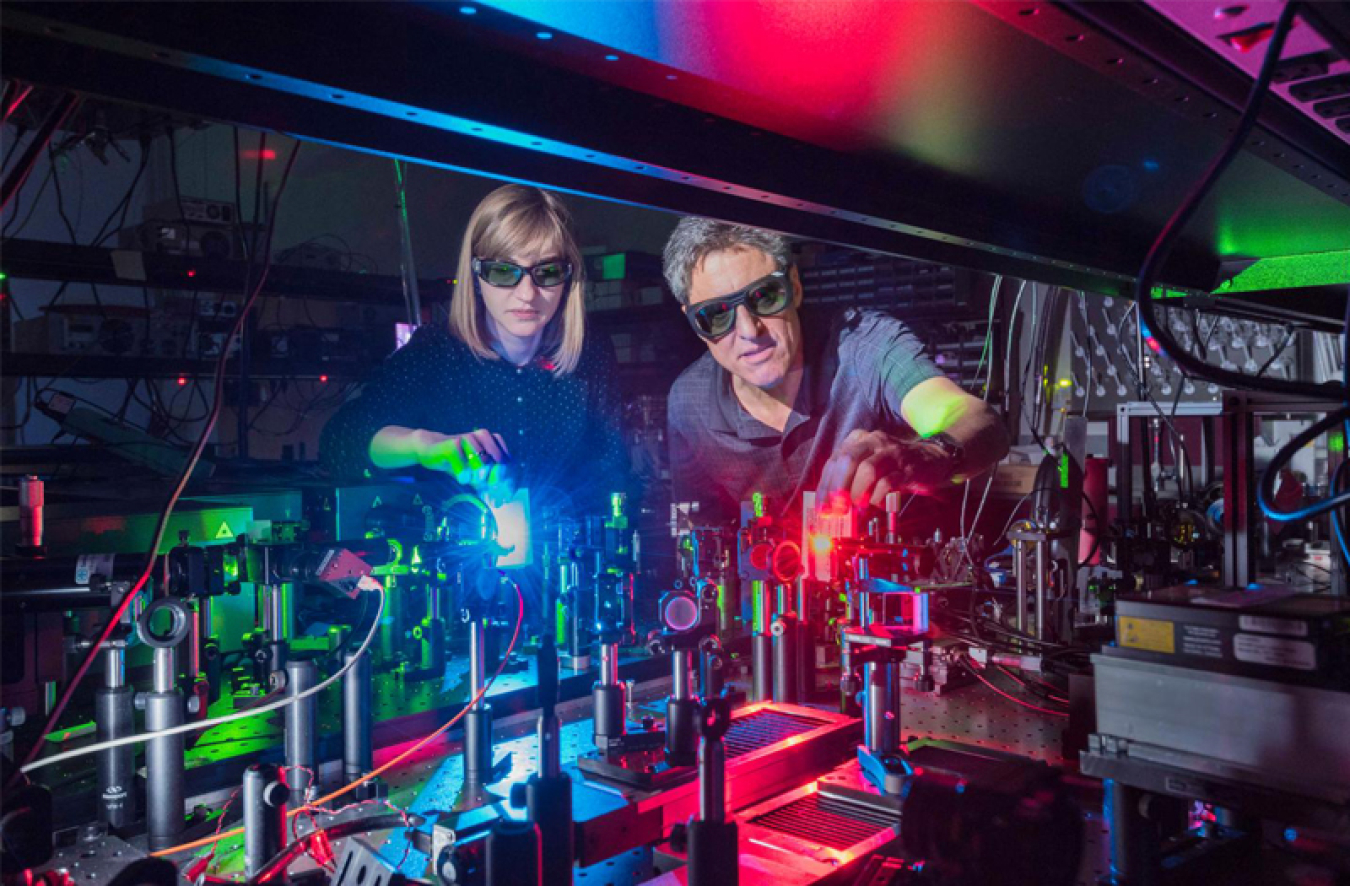

The report also considers the future of optics supplies. These components, including mirrors and lenses, are used in physics experiments that manipulate light and lasers. Although most optics components are not at risk at this time, our domestic vendors are small businesses that could suffer from skilled labor shortages or rising labor costs. Meanwhile, a niche area of X-ray optics for cutting-edge accelerators can be hard to source domestically.

SC is also one of the nation’s leading supporters of quantum computing research. A crucial system called a dilution refrigerator keeps quantum computing chips at very low temperatures to reduce errors. Up to 80 percent of the world’s dilution refrigerators are made in a single country outside the United States.

To bolster scientific supply chains, panelists propose a spectrum of near- to long-term opportunities. They recommend increased collaboration between DOE, SC, labs, and vendors; strategic investment programs that reduce vendor risk; and long-term workforce development for skilled jobs relevant to key technologies.

The report suggests SC could start by launching internal procurement conferences to share strategies and information about vendor capabilities. Mid-term recommendations include establishing Centers of Excellence at national labs to fabricate critical components in short supply and expanding interactions with small businesses capable of customizing components. A system for sharing inventory between SC sites could also reduce waste and costs.

Five to 10 years in the future, the panel urges greater collaboration between DOE and industry. For example, tech transfer programs for critical scientific equipment or technologies could help meet DOE needs while also leading to commercial spin-off applications of interest to industry. Public-private partnerships that forecast and then invest in emerging markets could also strengthen future supply chains.

Supply chain issues for critically important materials and products must be solved to ensure the continued success of these world-class facilities and instruments in bringing the benefits of DOE science and technology to the public. This report provides direction for moving forward.

The Office of Science is the single largest supporter of basic research in the physical sciences in the United States and is working to address some of the most pressing challenges of our time. For more information, please visit the Office of Science website.

Harriet Kung

Dr. Harriet Kung is Acting Director for the Office of Science in the U.S. Department of Energy (DOE). She also serves as the Deputy Director for Science Programs and is the senior career official providing scientific and management direction and oversight for the SC research programs, including Advanced Scientific Computing Research, Basic Energy Sciences, Biological and Environmental Research, Fusion Energy Sciences, High Energy Physics, and Nuclear Physics, as well as other supporting functions and offices. Dr. Kung served in various leadership roles in Basic Energy Sciences, the largest program in the Office of Science, from 2002 - 2020. Before joining DOE in 2002, Dr. Kung was a technical staff member and a project leader at Los Alamos National Laboratory. Her research focused primarily on nanoscale materials and high temperature superconductivity.

With over 20 years of service in the Department of Energy, Dr. Kung led and cultivated one of the nation’s premier physical sciences programs. During her tenure, she developed a new basic research paradigm in team-science approach to advance DOE’s science and energy missions by spearheading a decade-long, strategic planning initiative to assure timely, science-based solutions. She also positioned the Office of Science as a National Quantum Initiative leader by establishing strategies to capitalize on strong synergy between disciplines such as physics, biology, materials, and engineering, as well as the world-leading scientific user facilities. She has chaired and co-chaired high-level interagency working groups to develop and implement national science priorities.

Dr. Kung received her M.S. and Ph.D. degrees from Cornell University. She is the recipient of numerous awards including the Presidential Meritorious Executive Rank Award in 2009 and the Distinguished Executive Rank Award in 2022.