EERE Deputy Assistant Secretary of Renewable Power Alejandro Moreno attended the ribbon-cutting ceremony for a new 3-D printer at a GE research facility in Bergen, NY. Read how this technology is making tall wind turbines easier to build.

Office of Energy Efficiency & Renewable Energy

April 21, 2022

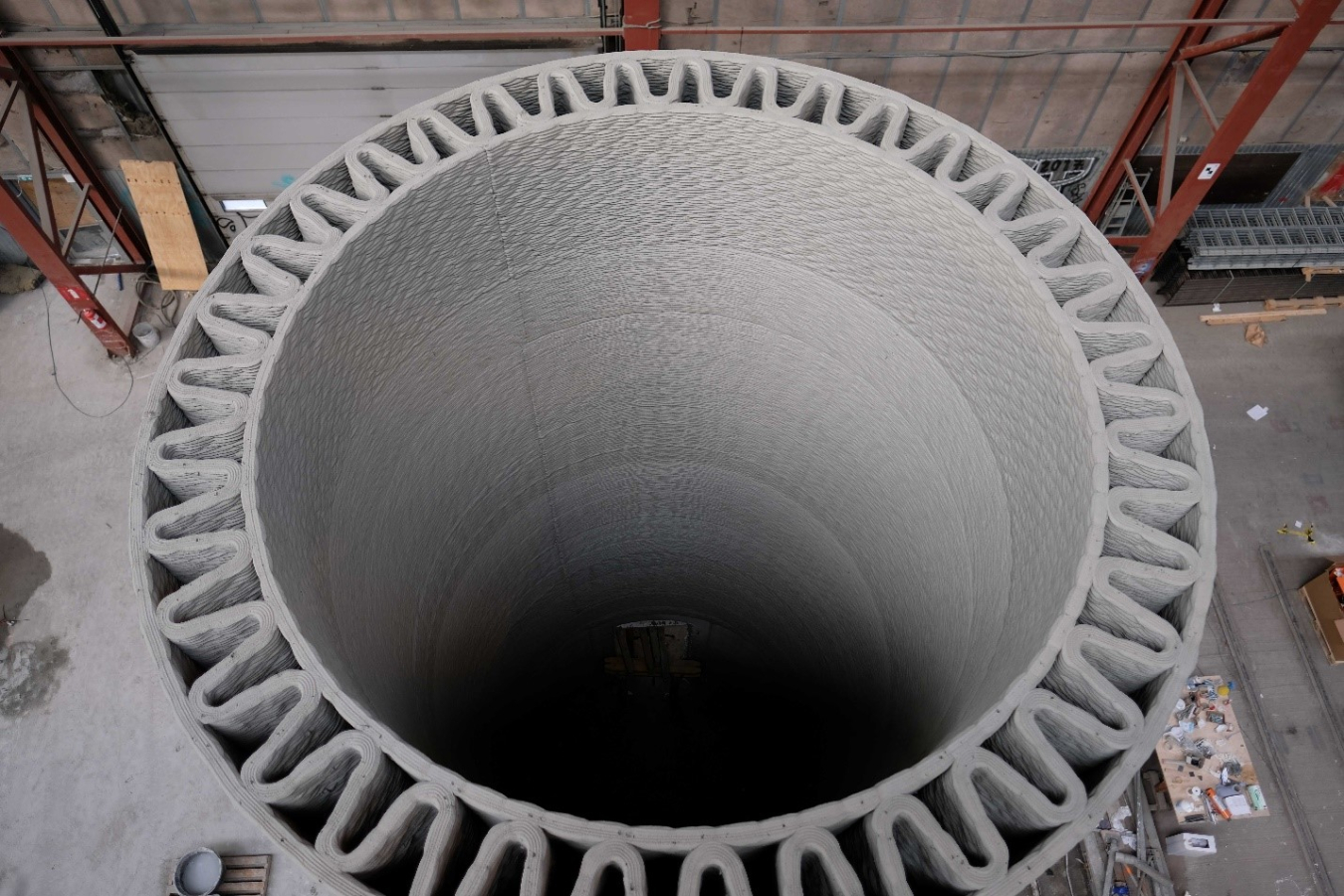

Height is might when it comes to wind turbine towers. The taller they are, the more energy they can harness. Transporting massive tower components to their installation sites is logistically challenging and costly, but GE Renewable Energy has a solution: 3-D printing the base of the concrete tower on site, making tall wind turbines easier to build, more efficient, and with lower transportation costs.

On April 21, EERE Deputy Assistant Secretary of Renewable Power Alejandro Moreno attended the ribbon-cutting ceremony for a new 3-D printer at a GE research facility in Bergen, NY, where experts are optimizing how concrete is 3-D printed and will industrialize the additive manufacturing process. EERE’s Wind Energy Technologies Office awarded GE Renewable Energy $5 million in 2020 to advance 3-D printing technology.

More Towers, More Power

This project could open the door to more wind installations across the country, enabling the scale-up of wind energy, which is crucial to achieve the Biden administration’s decarbonization goals. Today, wind power supplies about 9% of overall U.S. electricity generation, with an installed capacity of more than 120 gigawatts, but with these taller towers that can access higher-speed winds, we can greatly expand low-cost wind energy in regions like the Northeast and Southeast United States.

GE’s strategy for building a taller tower involves integrating the pedestal it sits on with the turbine foundation. GE’s printable pedestal and other stackable sections can reach heights above 20 meters, helping increase the height of the hub to above 140 meters, which is double the height from 20 years ago. (The hub holds the blades in place and connects the blades to the main shaft.)

Climate-Friendly Cost Savings

Installing taller wind towers makes economic sense, because more towers capturing more wind drives down the costs for each installation, lowers the overall cost of energy in some locations, and leads to lower electricity costs for consumers. Printing them on site solves the problem of transporting huge towers to places that don’t have access to railways or roadways that can handle large trucks, and it offers potential to capture more wind energy in more places. Wind is already cost-competitive in many parts of the United States, at about 2–3 cents per kilowatt-hour, but the Department of Energy plans to cut the cost of wind energy in half by 2030.

With the new research facility, GE Renewable Energy is working to make tower components and additive manufacturing operations more sustainable. In future years, the company is expecting to achieve up to a 15%–30% reduction in the amount of carbon-intense concrete and rebar used to build tower foundations. Cement production alone accounts for 7% of global CO2 emissions, which is a huge portion for a single contributor. And it’s inherently hard to decarbonize, so anything we can do to reduce our use of concrete is incredibly important. Researchers at the facility will also work to perfect using recycled wind turbine blades as a raw material input for the additive concrete. Ultimately GE is pursuing an additive concrete formula that is fully recyclable, further reducing carbon emissions.

Broader Benefits

3-D printing concrete at the installation means the height of the tower sections can be customized for different installations and locations. And on the wind farms that use this technology, new jobs will be created to build the wind towers.

Research and technology advancements could unlock and expand wind energy across the United States, giving more Americans access to clean power. Manufacturing techniques like 3-D printing that ease installation and cut transport costs can help make it happen.

Learn more about the state of the land-based wind industry by reading the 2021 wind market report.