Preparing for 24/7 operations to treat waste from Hanford’s large underground tanks isn’t a one-organization job. EM established the Technical Integration Team to progress the site-wide mission to treat waste under the DFLAW Program.

Office of Environmental Management

February 22, 2022

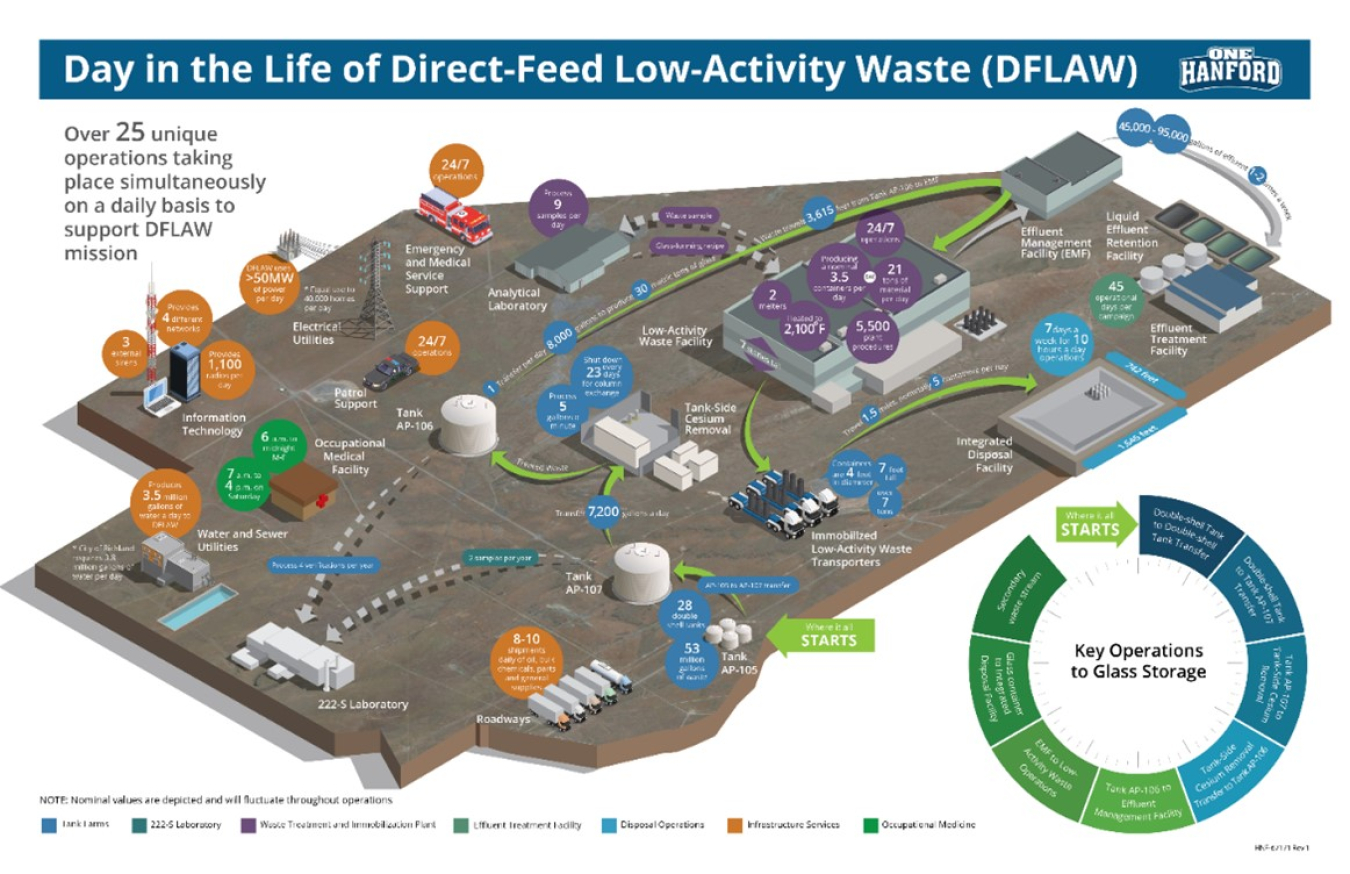

Hanford’s Direct-Feed Low-Activity Waste Program requires integration across all site prime contractors to deliver on more than 25 unique operations to treat waste from large underground tanks. The Technical Integration Team helps the contractors coordinate startup, commissioning and operation of program facilities.

RICHLAND, Wash. – Preparing for 24/7 operations to treat waste from Hanford’s large underground tanks isn’t a one-organization job. EM established the Technical Integration Team to progress the site-wide mission to treat waste under the Direct-Feed Low-Activity Waste (DFLAW) Program.

All of the site’s prime contractors and multiple EM offices are working together to prepare for starting the vitrification, or immobilization in glass, of waste by the end of next year. The team is made up of a cross section of Hanford Site contractors and EM managers that guide the startup, commissioning and operation of facilities needed to treat and dispose of the waste.

EM Office of River Protection (ORP) tank operations contractor Washington River Protection Solutions (WRPS) recently began operating the Tank-Side Cesium Removal system to remove radioactive solids from waste. After this initial treatment, the waste is being staged in a large underground tank that will feed the waste to the nearby Waste Treatment and Immobilization Plant (WTP).

Before the waste is sent to the plant in large batches, contractor Hanford Laboratory Management and Integration will test samples of waste pulled from the feed storage tank by vitrifying small batches of the waste in Hanford’s 222-S Laboratory. This is done to ensure the waste meets specifications for treatment in the WTP.

Contractor Bechtel National, Inc. (BNI) is commissioning the WTP, where the low-activity waste will be vitrified in large batches inside two giant melters and poured into large containers for disposal.

Contractor Central Plateau Cleanup Company will dispose of the containers in the nearby Integrated Disposal Facility, which provides permanent, environmentally safe disposition for the containers and other low-level waste from Hanford operations.

Throughout the process, essential services like water and power are provided by contractor Hanford Mission Integration Solutions.

“The Technical Integration Team has been up and running, meeting every two weeks for a couple of years,” said Mark Gerboth, WRPS mission integration and optimization manager. “We have been focusing on permitting and working with the DOE and regulatory agencies; the status of multiple DFLAW projects; and identifying program risks that will be mitigated to ensure our readiness to operate.”

In addition to preparing for treating tank waste, the team is also focusing on DFLAW operations.

“We’ve set up technical working groups within the team to focus on specific areas of interest in preparing for the startup of waste treatment and 24/7 operations under the DFLAW Program,” said Gerboth.

The working groups get together monthly and exchange ideas and information, including the status of the site-wide DFLAW activities. Members also identify and discuss issues that will be mitigated. The groups cover a wide range of topics, including secondary waste, cybersecurity, nuclear safety, waste feed qualifications, outage planning and even spare parts for 24/7 operations.

“Close collaboration with our Hanford colleagues is making the DFLAW Program successful,” said John Julyk, mission integration manager for BNI at WTP. “When we begin vitrifying tank waste, every step of the mission is important, from engineering through commissioning; treating the waste in Tank Farms and then safely turning it into glass in the WTP; and disposing of the glass-filled containers.”

All of those steps are critical parts of the DFLAW mission, and the One Hanford team is working together to safely treat and dispose of the waste to protect people in the region and the environment.

“This teamwork between the Department of Energy and the Hanford contractors is paramount to the success of the DFLAW Program,” said Delmar Noyes, ORP deputy assistant manager. “The collaboration emphasizes the One Hanford approach, and together, we are laying the foundation for a single contractor operating the DFLAW Program under the future Hanford Integrated Tank Disposition Contract.”

To receive the latest news and updates about the Office of Environmental Management, submit your e-mail address.