Lead Performer: Materials Modification Inc., Fairfax, VA

DOE Total Funding: $198,473

Project Term: June 29, 2020 – March 28, 2021

Funding Type: Small Business Innovation Research (SBIR) Project

Project Objective

The electricity consumption of residential and commercial buildings accounts for about 40% of the nation’s total energy demand. The Building Technologies Office (BTO) supports technologies that could lead to a significant reduction in the energy consumption of buildings. Heating and cooling in buildings consume considerable amounts of energy. Storing thermal energy from “waste” heat and using them as and when needed could significantly improve energy efficiency. Thus, Thermal Energy Storage (TES) technology plays a significant role in achieving BTO’s goal of reducing the energy use intensity of U.S. buildings by 30% by 2030, relative to 2010.

According to TES technology, heat energy is stored by heating or cooling a storage medium so that the stored energy can be used at a later time for heating and cooling applications. The advantages of using TES in an energy system include an increase in overall efficiency and better reliability, and this can, in turn, lead to better economics, reductions in investment and running costs, and emissions.

TES can be achieved by latent heat storage using phase change materials (PCMs). The main advantages of PCMs include high thermal storage density and small temperature swing. Paraffin materials are the common PCMs used in building applications. Due to their high cost, low volumetric energy capacities, and high combustibility, alternative PCMs are sought.

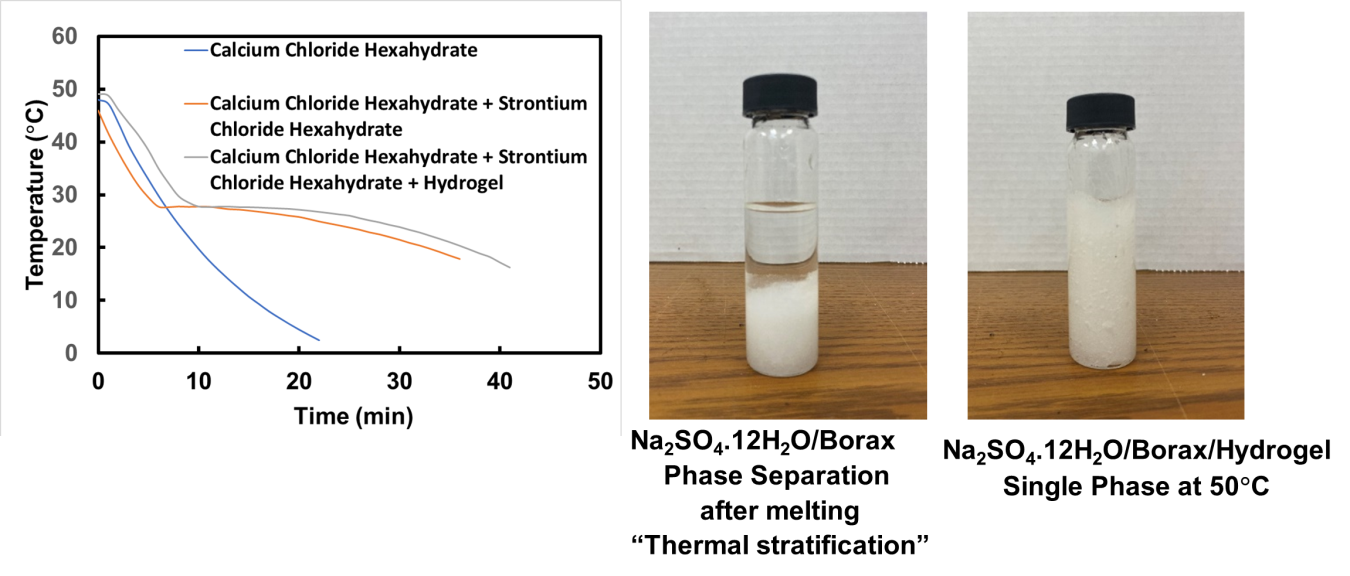

Inorganic hydrated salts have many advantages over organic PCMs, such as high thermal storage density, low-cost, and absence of toxicity issues. There are several nontoxic hydrated salts available that demonstrate phase change properties at a suitable window of melting temperature of 15-30°C for building applications. They exhibit high phase change enthalpy, making them promising in solar thermal utilization systems. However, many hydrated salts are associated with problems such as inherent supercooling, phase separation, and liquid leakage during solid-liquid phase change, which significantly limit their practical applications. Some solutions discussed in the literature include microencapsulation of hydrated salts to form a core-shell structure and impregnating melting hydrated salts into porous materials like expanded graphite. The main problems with microencapsulation technology are volume changes and the overflow of crystal water into the cavity of the spherical polymer shell materials of the impregnation of the hydrated salt composite PCMs that results in a reduction in heat storage density because of the high adsorbent to PCM ratio. Thus, there is a need for new PCMs that do not suffer from leakage problems and phase separation with no compromise on heat storage performance. In this Phase I SBIR project, inorganic hydrate PCMs with superior thermal storage properties and non-leakage characteristics will be prepared by incorporating them into nontoxic hydrogel composites. Physicochemical and thermal properties of the hydrogel composites relevant to the building thermal energy storage applications will be examined. The performance improvements of the hydrogel/hydrated inorganic salts based PCMs over commercially available paraffin-based PCMs will be demonstrated in this Phase I work.

Project Impact

The greatest potential impact for the building sector is in the potential development of a hydrogel composite approach to eliminate the drawbacks of salt hydrate PCMs. The novel PCMs developed in this project can improve the energy performance of buildings through their high energy storage capacity. When these PCMs are incorporated into the structural components of the building, such as walls, they can store and release energy as latent heat at low-temperature ranges, which results in a significant increase in the building’s thermal mass. The use of PCMs can lead to a significant reduction in heating and cooling loads and carbon emissions and provide improved occupant comfort.

Contacts

DOE Technology Manager: Sven Mumme

Lead Performer: Kris Rangan, Materials Modification Inc.