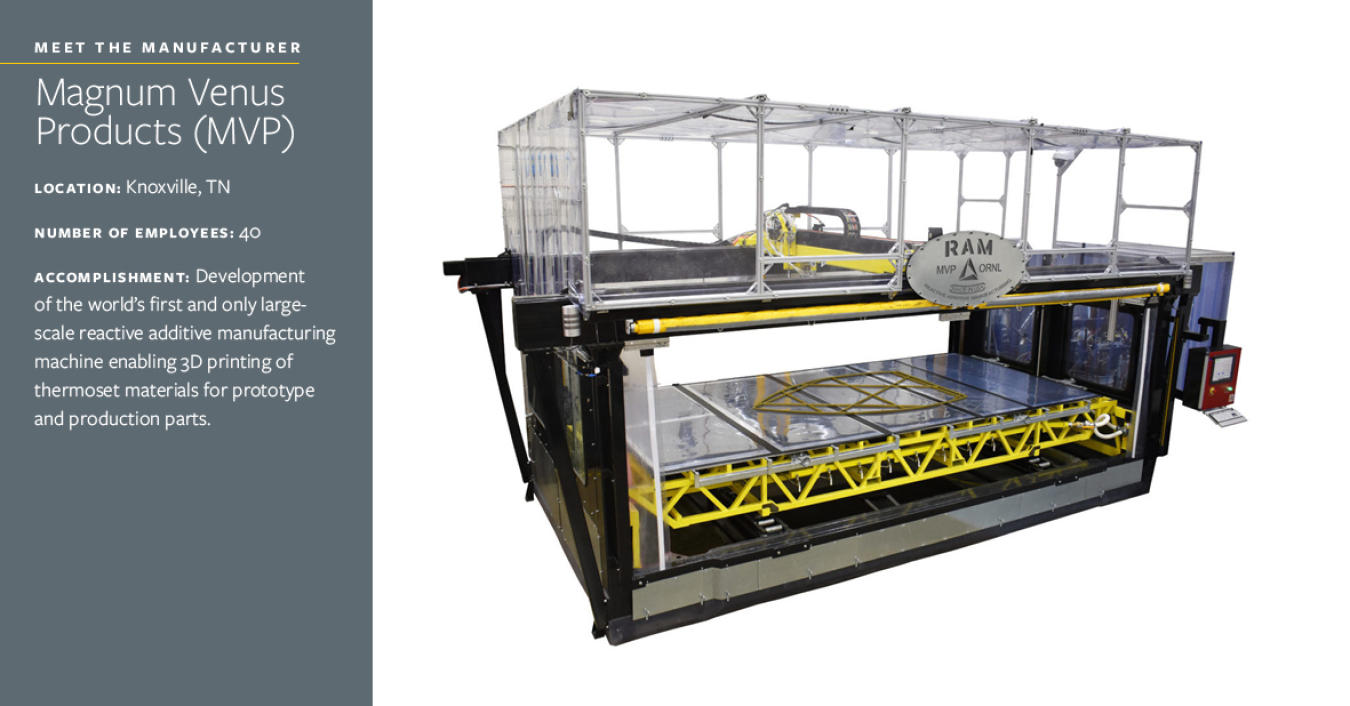

Image courtesy Magnum Venus Products

Magnum Venus Products (MVP, a leading manufacturer of composites application equipment, collaborated with Polynt and the Department of Energy’s Oak Ridge National Laboratory to deploy the first large-scale reactive polymer additive manufacturing system commercially available to industry. MVP’s Reactive Additive Manufacturing (RAM) machine, first announced in March, and Polynt’s Reactive Additive Deposition (PRD1520) material together are reimagining additive manufacturing to enable fabrication of thermoset materials at large-scale. While thermoplastic materials have become the norm in additive manufacturing, this thermoset technology has the potential to revolutionize additive manufacturing and meet demands for stronger, more cost-effective solutions while remaining energy efficient. The advantage lies in crosslinking polymers between printed layers, resulting in stronger, more thermo-tolerant products. By collaborating with ORNL, MVP was able to scale up the technology from a benchtop solution to a commercially ready machine. Polynt’s PRD 1520 is a specifically formulated reactive monomer material developed for use in the MVP RAM machine. The material boasts superior interlaminar adhesion, exceptional machinability, and high heat distortion temperature compatible with aerospace grade tooling application.