This blog is part of a series that explores offshore wind technical challenges that are different in the U.S. than in other countries.

Office of Energy Efficiency & Renewable Energy

December 19, 2017

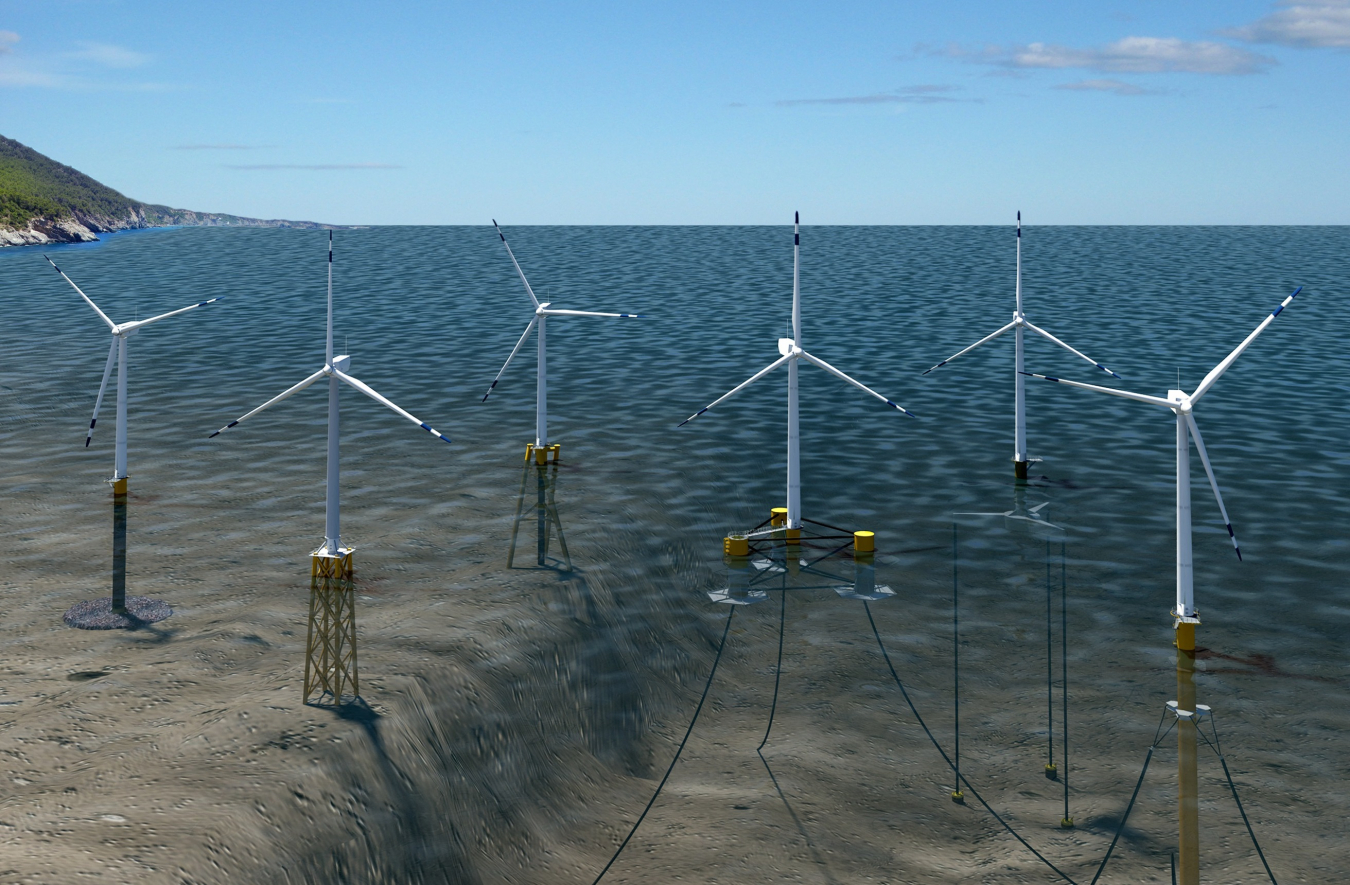

Illustration by Josh Bauer, National Renewable Energy Laboratory (NREL)

This blog is part of a series that explores offshore wind technical challenges that are different in the U.S. than in other countries.

While the first blog in this series focused on the floating foundations needed for U.S. offshore wind development in deep waters, this blog examines innovations in fixed-bottom foundations. With more than 40% of the U.S. offshore wind resource located where the water is less than 60 meters (100 feet) deep, foundations fixed to the seafloor are feasible in many locations.

Jacket Foundations and Monopiles

Most offshore wind installations to date (accounting for 80% of installed capacity worldwide) have used monopile foundations, which are cylindrical structures driven into the seafloor and attached to the bottom of the wind turbine tower.

As offshore wind projects move further from shore, jacket structures, which typically consist of four legs connected by braces, are becoming more common. Block Island—the first U.S. offshore wind farm—used a “gulf-style” jacket foundation with an installation method adapted from the offshore oil and gas industry.

However, there are several other fixed-bottom foundation types that may prove to be better options for U.S. conditions, including sandy seabeds, soil types that vary across small areas, and the need to comply with environmental regulations. For example, monopiles are driven deep into the seabed using large pile driving hammers — a noisy process that can be harmful or annoying to marine animals, potentially leading to construction delays during seasonal migrations.

Offshore wind turbines are getting larger, complicating the use of monopile foundations. Most turbines being installed offshore today are 5–6 megawatts (MW) in capacity (compared to 2 MW for land-based turbines). The newest class of offshore wind turbines being developed are 9–9.5 MW with a rotor diameter over 500 feet, similar to the height of the Washington Monument. To support such a large turbine, the foundation needs to have a lot of mass, and therefore a lot of capital cost, under the water. This is one of the reasons why jacket foundations, which use a lattice structure to support the weight while using less steel, are becoming more common.

Offshore wind turbine with Twisted Jacket Foundation.

The Twisted Jacket

Louisiana-based Keystone Engineering has modified the traditional jacket design to create a “twisted jacket” with the legs angled around a central column, which uses less steel and is cheaper than traditional jacket foundations. The twisted jacket technology has been successfully demonstrated in the oil and gas industry as suitable for a wide range of seabed conditions. Keystone Engineering is one of several U.S. companies interested in leveraging their oil and gas experience to support renewable applications.

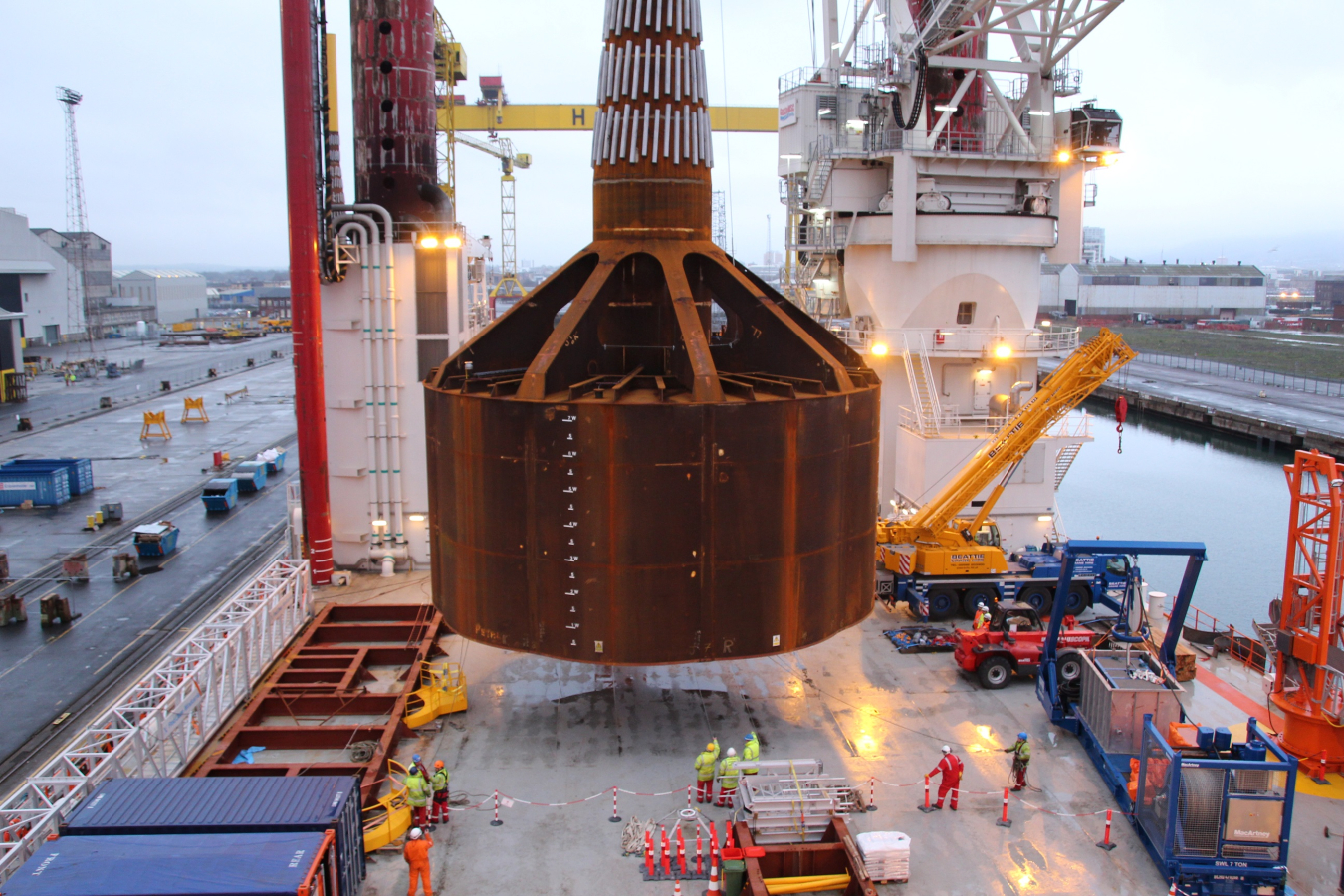

Another innovative type of foundation derived from the oil and gas industry is the suction bucket. An example is Universal Foundation’s Mono Bucket, which combines a monopile with a suction bucket designed for soft soil conditions. Additionally, the foundation can be fitted with an “ice cone” at the water line. This can prevent ice from building up on the foundation—a potential problem for offshore wind in fresh water such as in the Great Lakes.

While the Mono Bucket has been demonstrated for use with meteorological towers, the first offshore wind project planning to use this new foundation type is the Lake Erie Energy Development Corporation’s (LEEDCo’s) Icebreaker project, which is supported by DOE’s offshore wind demonstration program. The Mono Bucket will reduce installation time, costs, and environmental impacts compared to traditional foundations that require pile driving. It also has broader national applicability for offshore wind installations off the Atlantic and Gulf Coasts.

What’s Next

With offshore wind just getting off the ground in the U.S., there is still a need for more extensive site assessments to better understand seafloor conditions as well as to inform the design and siting of offshore wind. Improvements in offshore wind site characterization and technology advancement can reduce costs by increasing energy production; and by reducing development timelines, capital costs, and operations and maintenance costs. Some topics that the new offshore wind R&D consortium may tackle include validating innovative site characterization methodologies and models in order to minimize the need for extensive on-site data collection.

The diversity and ingenuity displayed in addressing this formidable engineering challenge reflects the obstacles overcome by American companies, supported by DOE’s Office of Energy Efficiency and Renewable Energy. Whether the foundation floats or is fixed, offshore wind is poised to become a strong, steady and reliable source of electricity.

Liz Hartman

Liz Hartman is the Communications Lead for DOE’s Wind Energy Technologies Office, and formerly (2009–2016) the Communications Lead for EERE’s combined Wind and Water Power Technologies Office.

Liz is a graduate of Cornell University with a B.S. in Natural Resources and an M.P.A. in Environmental Policy.

Articles by Liz Hartman

-

Learn more about efforts to develop America's vast offshore wind resources.

Learn more about efforts to develop America's vast offshore wind resources. -

Brush up on your knowledge of wind! Get the details on a few of the lesser-known wind energy facts.

Brush up on your knowledge of wind! Get the details on a few of the lesser-known wind energy facts. -

Learn about key facts related to wind turbines used in distributed applications.

Learn about key facts related to wind turbines used in distributed applications. -

Wind power capacity in the United States continued to experience strong growth in 2017.

Wind power capacity in the United States continued to experience strong growth in 2017. -

Offshore wind turbines on the Atlantic coast (as well as the Gulf Mexico) have several challenges to contend with—including hurricanes.

Offshore wind turbines on the Atlantic coast (as well as the Gulf Mexico) have several challenges to contend with—including hurricanes. -

This blog is part of a series that explores offshore wind technical challenges that are different in the U.S. than in other countries.

This blog is part of a series that explores offshore wind technical challenges that are different in the U.S. than in other countries. -

This blog is part of a series that explores offshore wind technical challenges that are different in the United States than in other countries.

This blog is part of a series that explores offshore wind technical challenges that are different in the United States than in other countries. -

New breakthroughs could cut the cost of wind energy in half by 2030—making it fully competitive with the fuel cost of natural gas.

New breakthroughs could cut the cost of wind energy in half by 2030—making it fully competitive with the fuel cost of natural gas. -

From utility-scale wind farms to the nation’s first offshore wind project, the U.S. wind industry continued to grow in 2016.

From utility-scale wind farms to the nation’s first offshore wind project, the U.S. wind industry continued to grow in 2016. -

Test your energy knowledge by checking out these surprising facts about hydropower.

-

The five things you should know about wind power and it's impact in the United States.

-

A new report evaluating the potential for offshore wind energy development across U.S. coasts found that even if only 1% of the technical resource potential is recovered, nearly 6.5 million homes could be powered by offshore wind energy.

-

If we harnessed America's vast, untapped offshore wind energy resources -- what would be the impact?