Additive manufacturing allows researchers to create physical, three-dimensional objects directly from a computer design file.

Office of Energy Efficiency & Renewable Energy

October 16, 2017In simplest terms, additive manufacturing is 3D printing.

This emerging manufacturing practice allows researchers to create physical, three-dimensional objects directly from a computer design file. It’s similar to how common desktop printers form images—but instead of ink, 3D printers use a wide variety of materials ranging from polymer composites, metals and ceramics to food, foams, gels, and even living tissue.

Watch and learn about additive manufacturing, a process commonly referred to as 3D printing.

History of Additive Manufacturing

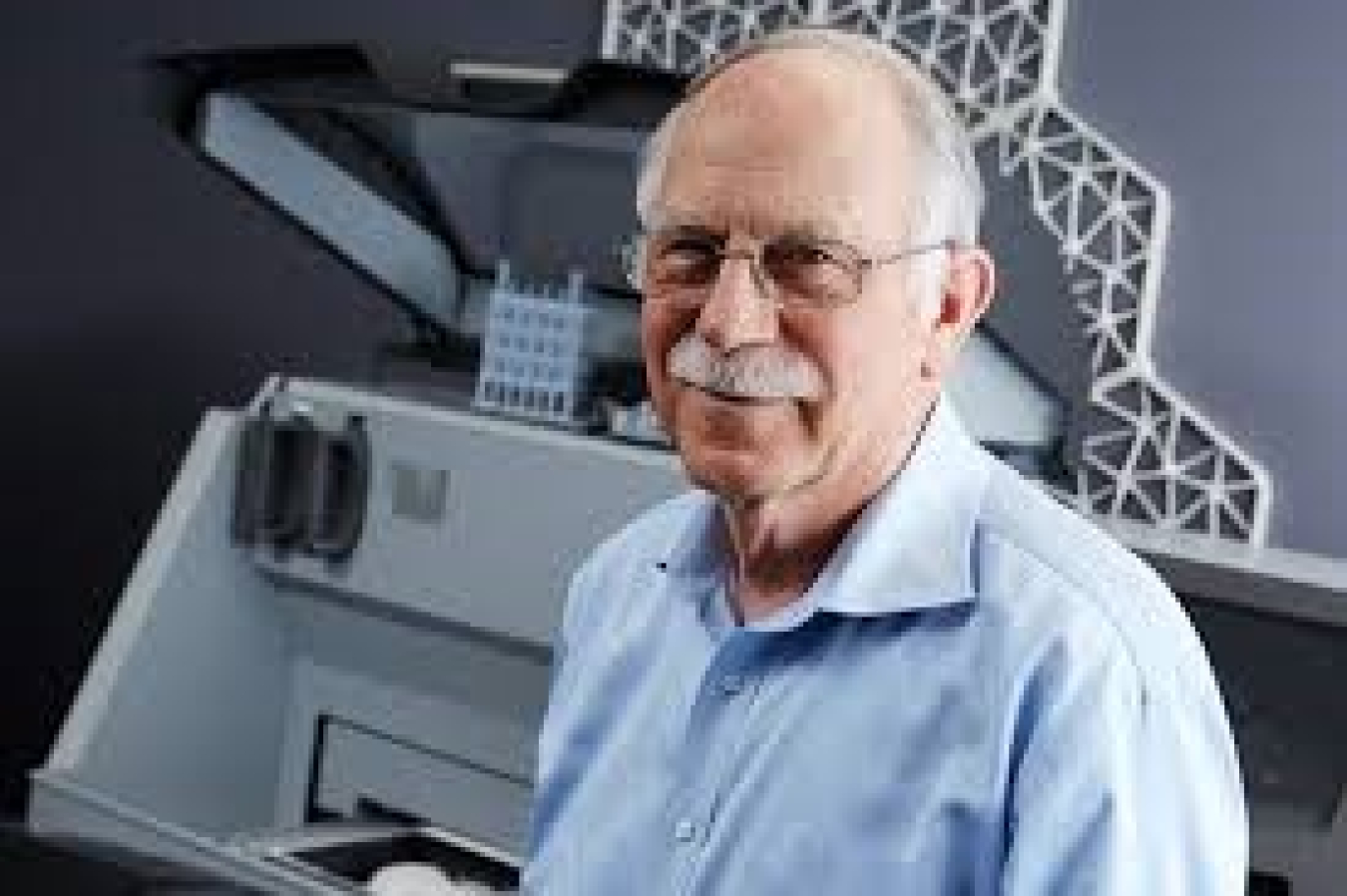

Chuck Hull, the inventor of the solid imaging process known as stereolithography.

Additive manufacturing started in the 1980s when Chuck Hull invented a process called stereolithography, now known as 3D printing. He discovered the method, which used UV lasers to create 3D objects layer by layer, after becoming frustrated with the long production times of prototyping. This sparked the next wave of manufacturing practices, and in 1986, he successfully patented his invention, eventually becoming the father of 3D printing.

Additive Manufacturing Today

Additive manufacturing is gaining industry momentum and changing the way manufacturers tackle science-based challenges. According to a leading 3D printing insights report, the 3D printing industry is expected to grow by more than 31% per year until 2020 and generate more than $21 billion in revenue.

Why?

Because of its potential.

Additive manufacturing reduces energy use by 25% and can cut waste and materials costs by up to 90%1, compared to traditional manufacturing methods. Additionally, this method also has the ability to improve energy productivity, allow for greater design flexibility and reduce production time—all while creating high-impact job opportunities.

A Federal Focus

As a result of these benefits, additive manufacturing is a primary focus area for the U.S. Department of Energy. In partnership with Oak Ridge National Laboratory (ORNL), the Advanced Manufacturing Office (AMO) has printed everything from large items such as houses and sports cars to functional nozzles and heat exchangers for public-private partnerships.

Within the next five years, AMO aims to use additive manufacturing methods to achieve greater productivity in the transportation, energy production, manufacturing, aerospace, defense, and buildings sectors.

View just a few products printed out of AMO’s Manufacturing Demonstration Facility located at ORNL.

1The Economist, “The Printed World: Threedimensional printing from digital designs,” 10 February 2011. www.economist.com/node/18114221

Learn more about additive manufacturing and other manufacturing practices.