Because smart meters and advanced metering infrastructure cannot locate leaks, they are not included in this list of leak-detection technologies. Although they cannot detect leaks directly, these meters can help water managers determine if a leak exists. Learn more about using smart water meters.

The United States loses 2 trillion gallons of treated drinking water each year from water main breaks that are often caused by undetected leaks according to the Association of Civil Engineers 2017 Infrastructure Report Card. This report card highlights that much of the country’s water infrastructure is deteriorating and there is an increased need to evaluate distribution systems and develop plans for maintenance and repair.

Identifying and locating distribution system leaks can be difficult. However, targeting problem areas for repair or replacement is critical for effective resource management and water conservation. To this end, the Federal Energy Management Program identified several leak-detection technologies that can assist federal agencies in detecting and consequently repairing water leaks.

The technologies and methods presented here are relevant to the federal sector, are commercially available, and potentially can lead to significant water-savings. Leak detection technology options are provided for small to medium systems (such as leaks at a single facility) and large systems (such as leaks in a utility’s distribution lines). The intent is to provide agencies with key and possibly overlooked information that can guide deployment of innovative products and systems.

A water manager must have a set of overarching policy goals, an assessment of current water use and costs, and a developed water balance. The water balance gives an approximation of water losses currently in the system (e.g., in thousands of gallons (kgal) per year). Combining this quantity with the cost basis for water charges (e.g., $/kgal) provides the potential cost savings from leak detection and repair.

Technology Options

The technology options described here are divided into two broad categories.

Rough cost approximations for each technology are presented on a scale as $.

$ = $200 - $5,000

$$ = Greater than $5,000 but less than $20,000

$$$ = $20,000-plus

Small-to-Medium Systems

Leak detection technology for service lines in a distribution systems that supply water to a single building or a small set of buildings. These include:

- Noise loggers

- Listening sticks

- Hand-held thermal imaging.

Large Systems

Leak detection technology for main lines in a distribution system that can supply water throughout a large campus

- In-pipe sensors

- Fiber optics

- Satellite

- Ground penetration

- Drone-operated thermal imaging.

These technology options may be used in combination depending on the system size and need of the site. In many cases, utilities and owners of larger systems can and do use combinations of technologies.

Noise loggers, listening sticks, and thermal imaging can be suitable for service lines that feed small-to-medium systems. Examples of small systems are single-building sites and industrial uses (such as process water in manufacturing facilities), while medium systems may be multi-building campuses with inter-building distribution piping.

Noise Loggers

Acoustic leak-detection technologies use sound waves to help locate leaks in distribution systems and prioritize repairs by identifying the largest leaks. Leaks create a distinctive noise as water leaves the pipe, with smaller leaks producing a higher-frequency sound and larger leaks typically having a lower-frequency sound. This technology includes a listening head and digital recorder in a single sensor. The noise logger can be attached magnetically along the distribution system (e.g., key junctions, main valves, or hydrants) and left in place for extended periods or moved as needed to record noise levels and detect leaks. Loggers collect acoustic data during low-use hours, and a technician or software then analyzes data to determine if and where there is a leak.

System Size: Small-to-medium

Cost: $-$$ depending on system size—includes loggers and costs for installation, maintenance, and data gathering and interpretation

Considerations:

- Works best on cast iron, ductile iron, steel, concrete, and transite pipes.

- PVC pipes require longer periods of recorded data and sensors must be closer together.

- Higher end models can provide more interpretation of leaks. Advanced noise loggers can perform correlation which assists in pinpointing the distance to a leak down a pipeline.

- Lower-end models (i.e., those that can identify leaks but do not have a correlation function) generally need more data interpretation and consequent leak pinpointing using leak correlators.

A leak correlator is a device that analyzes the sound waves received at two contact points (e.g., valves or hydrants) located on opposite sides of a leak. Microphones connected to the pair of contact points transmit the leak noise information wirelessly to the correlator. The correlator determines the time delay between when the leak sound arrives at the closer contact point versus the further contact point and uses this time delay, along with user-specified parameters for the pipe material and diameter, to calculate the position of the leak.

Listening Sticks

Acoustic-based handheld devices allow the technician to manually check for leaks along exposed pipes or contact points (hydrants, valves, meters, etc.) in a system. Digital models have various frequency filters and are generally much easier to operate. These devices can be used with any sized system, but because of the intensive staff hours required to analyze a system, it may only be cost effective on small systems or as a supplement to another technology. Listening sticks will provide knowledge of leaks nearby but will require additional steps (such as using a correlator) to pinpoint the location of the leak.

System Size: Small

Cost: $ device plus labor hours needed for detection

Considerations:

- Contact points must be accessible (e.g., above ground or easily accessible underground).

- Difficult to use without proper training and orientation from an experienced user.

Hand-held Thermal Imaging

Handheld thermal imaging cameras detect water leaks in or around walls and structures. Assuming an average water temperature of 40°F-70°F, leaks will typically be warmer than the surroundings during winter months, and cooler than the surroundings during summer months.

System size: Small (handheld)

Cost: $ device plus labor hours needed for detection

Considerations:

- Relatively easy to use technology with minimal training required.

- Technology fairly limited to only leaks inside buildings.

Technologies suitable for large-scale systems typically have high capital costs and are most likely to be used by utilities or specialized contractors. Several of these technologies, including in-pipe sensors, fiber optics, satellite imaging, ground-penetrating radar, and drone operated thermal imaging function best with larger diameter pipes.

In-Pipe Sensors

This generally is a one-time service provided by a vendor that runs a device with either acoustic, pressure, or electromagnetic sensors through pipes to detect leaks. Devices can be tethered or free-floating in watered lines or can use robotic crawlers in de-watered lines. The sensors use GPS information to digitally map pipe systems during the inspections. The exact locations of detected leaks are marked on a pipe map.

System size: Large

Cost: Deployment $$$—additional charges can range per mile surveyed

Considerations:

- One-time service from a vendor.

- Leaks of less than 1 gpm may not be detected.

- Pipes must generally be 8-in. diameter or larger.

- In potable water lines, the pipe may require thorough cleaning after devices have been sent through the pipeline.

Fiber Optics

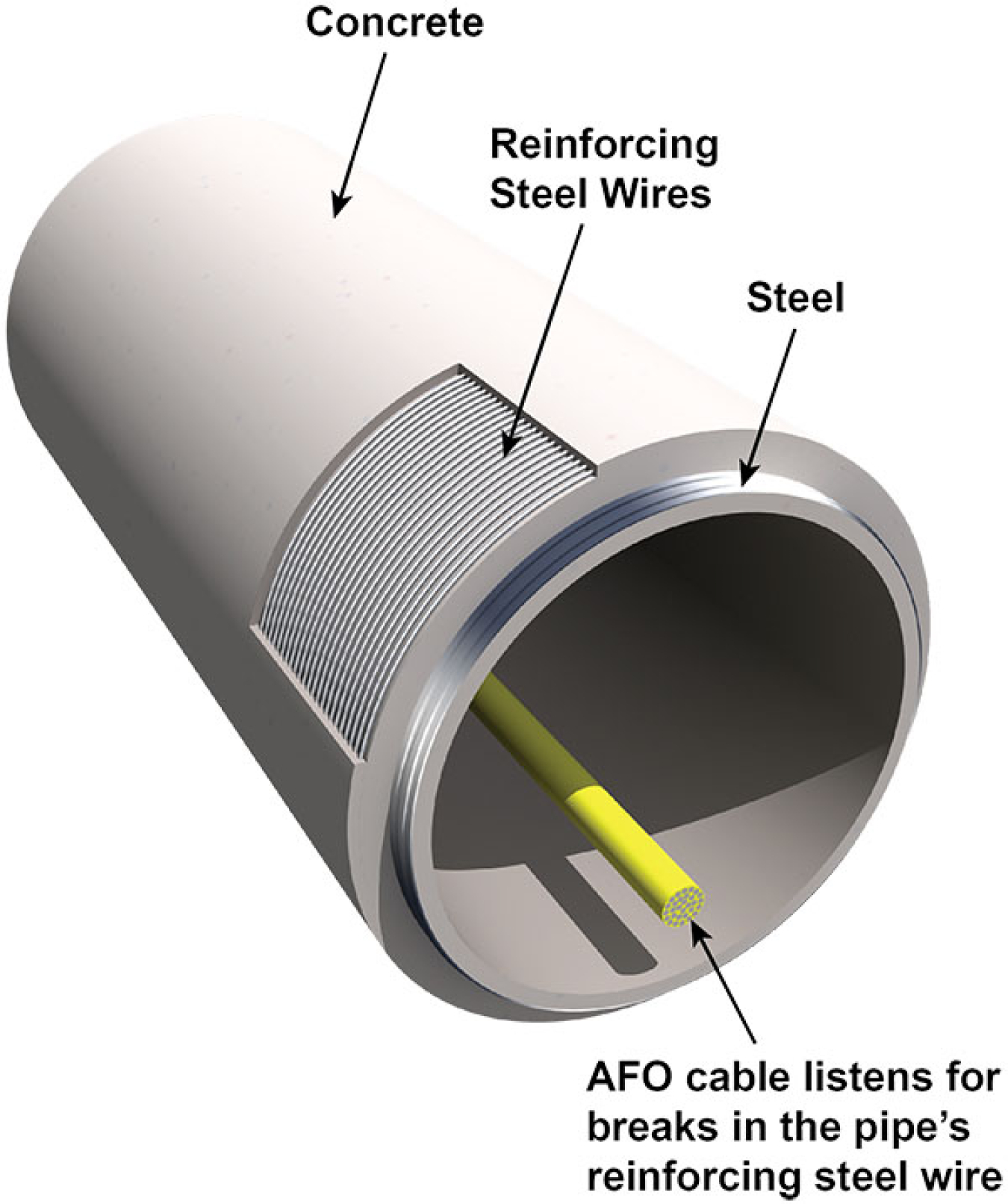

Acoustic fiber optic monitoring lines can be placed inside or on the outside of prestressed concrete cylinder pipe (PCCP) lines. These systems can detect breaks in reinforcing steel wires within the structure of the pipe. Acoustic fiber optic systems in or on PCCP lines can detect wear on the pipes but technically do not detect leaks.

System size: Large

Cost: Deployment $$—with additional charges for ongoing monitoring, which may be billed per mile

Considerations:

- Used only with large-diameter PCCP lines; not applicable to other materials.

- Remote monitoring service is an additional ongoing cost.

- Generally, not cost effective for retrofitting but can be used for new construction and pipe replacements.

Satellite

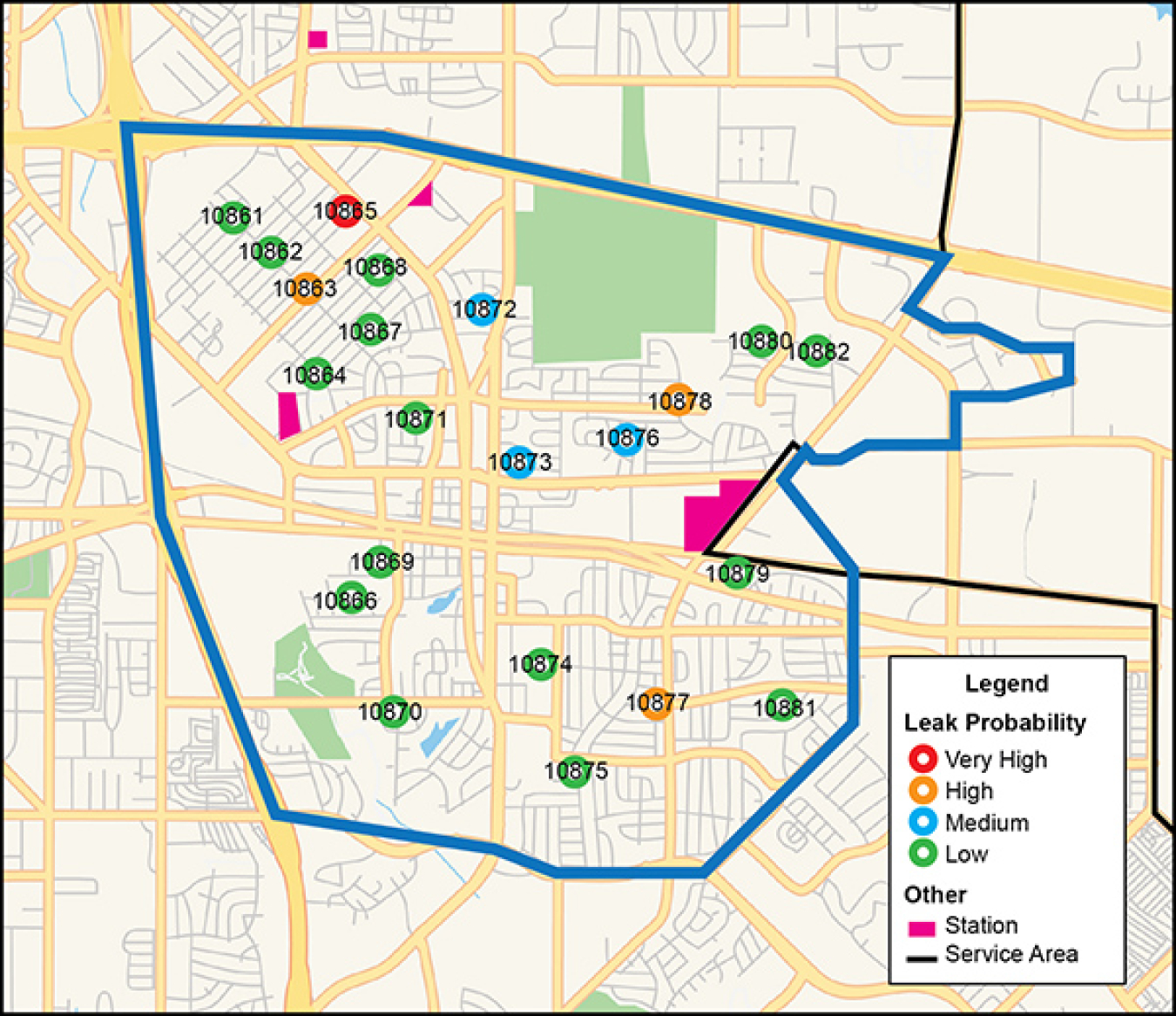

Satellites carrying radar sensors can scan areas on the order of 1000 mi2 to search for specific treated drinking water signatures. Synthetic Aperture Radar sensors can detect relatively small water leaks up to 12 ft below the surface of the ground. Algorithms process the data and reports are generated from client-provided GIS pipeline maps.

If a water manager does not have a complete pipe map, the report can be generated from paper maps; however, the survey will take more time and be more expensive. The report indicates points of interest (POI) that are approximately the size of a city block; these POIs signify a high likelihood of a water leak. A secondary leak-detection team then is deployed to pinpoint leaks and repair them. Preliminary targeting of POIs that need to be inspected can reduce staff hours required for secondary leak-detection teams in large systems.

System size: Large

Cost: $$$ per deployment plus additional staff hours needed for detection

Considerations:

- One-time service from a vendor.

- Only practical for large water distribution of pipe systems.

- Best suited for sites with detailed GIS pipeline data.

Ground Penetrating Radar

Ground penetrating radar (GPR) sends electromagnetic waves into the ground; the waves are reflected off objects, and the device uses returned waves to create a picture of subsurface objects. The image depicts pipe breaks and underground pools of water. Some GPR models can create three-dimensional images of underground objects. This technology requires a trained technician who operates the device by walking it directly over the pipe system. Significant experience is needed to interpret the returned data to detect leaks.

System size: Large

Cost: $$–$$$ for device plus additional staff hours needed to operate the GPR device

Considerations:

- The path of the pipeline (greater than 1-in. in diameter) must be marked on the ground before use.

- The pipeline must be unobstructed by vegetation and buildings.

- Naturally occurring groundwater can interfere with leak detection.

- Extensive staff hours needed for a comprehensive system inspection.

Drone Operated Thermal Imaging

Drone operated thermal imaging technology detects leaks in long transmission mains buried under roads or fields by measuring soil temperature differences. Assuming an average water temperature of 40–70°F, leaks will typically be warmer than the surroundings during winter months, and cooler than the surroundings during summer months.

System size: Large

Cost: $$ plus labor hours needed for detection

Considerations:

- Must have a large enough temperature difference between ambient air and temperature of the water—less effective during the Spring and Fall shoulder seasons.

- In-ground pipe leaks may be masked by groundwater or vegetation.

- No indication of the size of a leak.

- Drone devices require flight training for the operator.

- There may be restrictions to drone operation depending on the site's functions and mission.

More Opportunities

Read about these additional water-efficient technology opportunities.