The scientists, engineers, and analysts of the Co-Optimization of Fuels & Engines (Co-Optima) initiative investigated fuels and engines as dynamic design variables that can work together to boost efficiency and performance, while minimizing emissions. Potential benefits include dramatic improvements in vehicle fuel economy and increases in the use of domestically sourced fuel for transportation. This, in turn, has the potential to create new U.S. jobs and keep energy dollars in the United States, while reducing emissions and costs for consumers and commercial operators at the pump.

Solutions for Vehicles of All Classes

In addition to exploring synergies among the fuels, spark-ignition (SI) engines, and powertrains used in today’s traditional light-duty (LD) vehicles, the Co-Optima initiative investigated multimode, advanced compression-ignition (ACI), and mixing-controlled compression ignition (MCCI) solutions for the full range of LD, medium-duty (MD) and heavy-duty (HD) vehicles, along with opportunities related to hybrid and plug-in hybrid technologies. The objective scientific outcomes of this research is designed to provide American industry and policymakers with the knowledge, data, and tools needed to decide which changes could prove most viable and beneficial for drivers, businesses, and the environment.

Pinpointing Fuel Properties for Optimal Performance

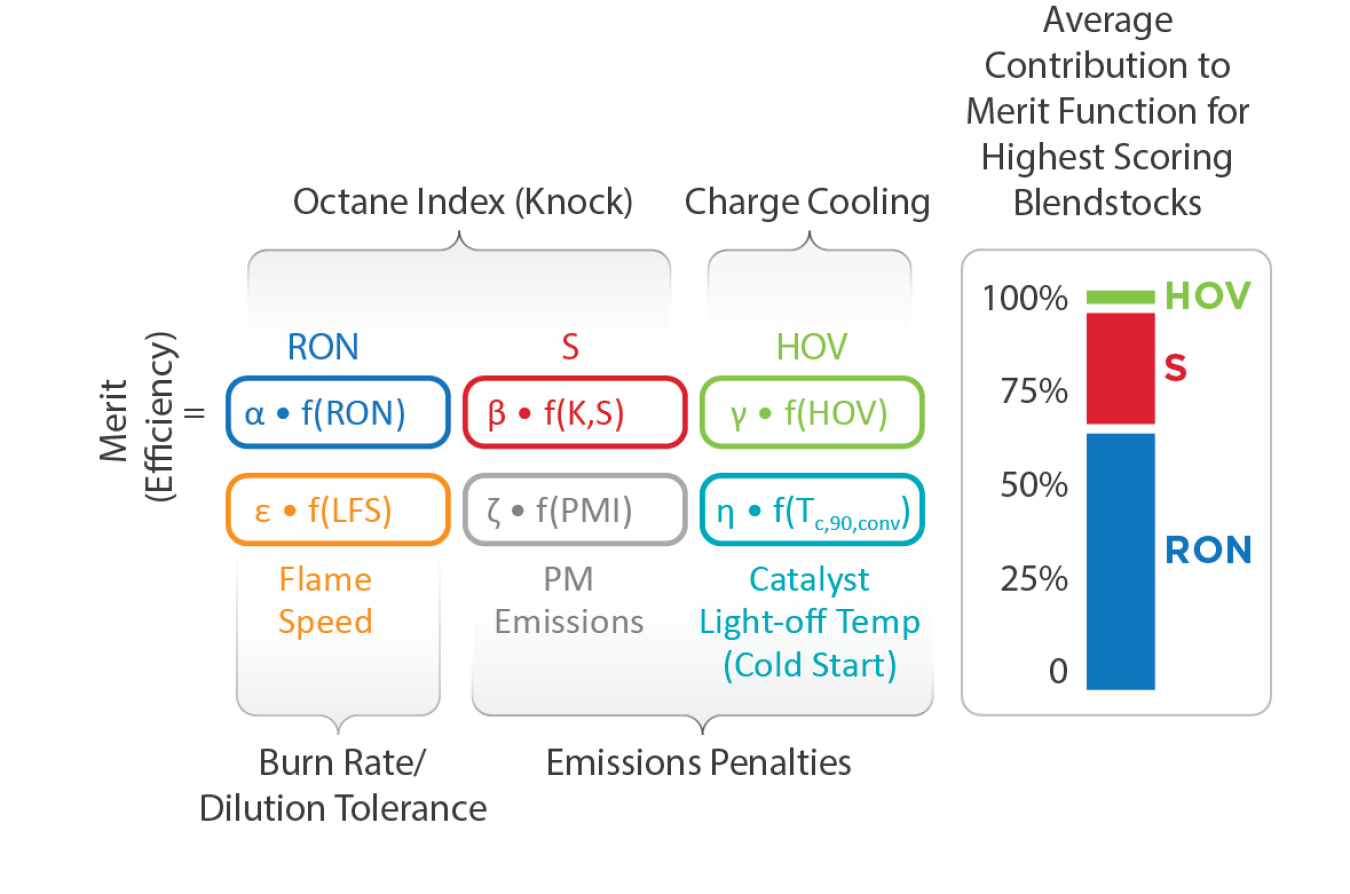

Co-Optima Merit Function. See the Merit Function Report for a more detailed definitions of variables, an explanation of the algebraic formula, and how the formula is applied.

Researchers have long recognized the potential for fuels with higher research octane number (RON), octane sensitivity (S), and heat of vaporization (HOV) to increase engine efficiency. For the first time, the distinct algebraic form of the Co-Optima-developed merit function has assigned a numerical value corresponding to possible efficiency gains from these and additional fuel properties in a co-optimized engine relative to regular (E10) gasoline. This has showed researchers how fuel properties—RON, S, HOV, flame speed, particulate matter index, and the catalyst light-off temperature—interact and trade off, making it possible to rank fuels on a quantitative basis. This work has supplied a new fundamental understanding of how fuel properties, engine parameters, and fuel composition interact to impact engine efficiency and emissions.

Rigorous Screening to Identify Blendstock Potential

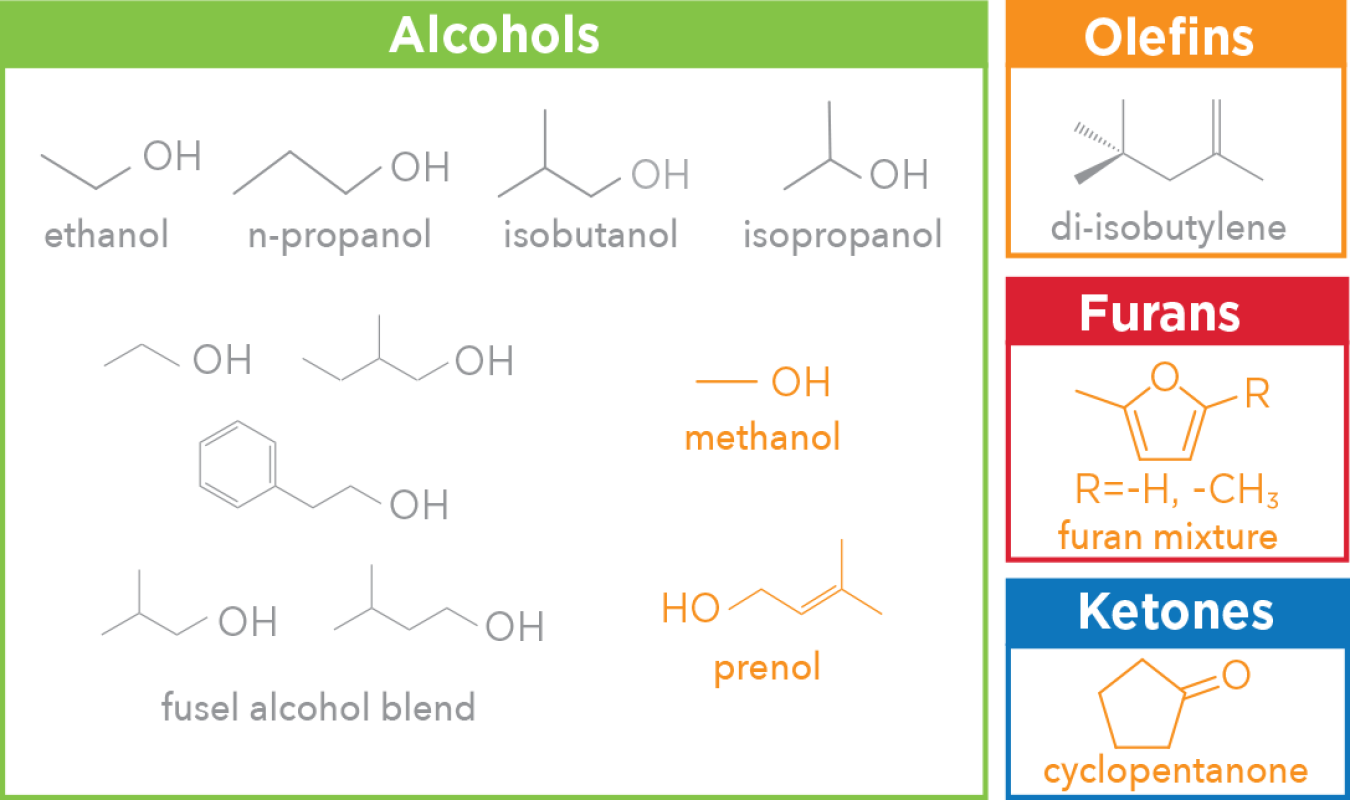

Blendstocks with Potential to Increase Boosted SI Engine Efficiency. Six candidate blendstocks with the fewest significant technical barriers to adoption are highlighted in orange. Note: CH3=methyl, H=hydrogen, O=oxygen, OH and HO=hydroxide.

A major portion of Co-Optima research focused on identifying blendstocks that can be added to conventional liquid fuels to tailor the fuel properties. Researchers considered blendstocks that can be produced from a wide variety of domestic resources, including non-food domestic biomass such as forestry and agricultural waste.

Following studies of more than 400 potential blendstocks, rigorous Co-Optima screening and evaluation led to initial identification of eight representative high-octane blendstocks across five chemical groups that exhibited properties with enough promise to warrant further investigation. Subsequent research has pinpointed 10 blendstocks from four chemical families with the greatest potential to increase boosted SI engine efficiency. Of these ten, six have the fewest significant technical barriers to adoption. A systematic assessment of hydrocarbon and oxygenate functional groups for possible use as diesel-like blendstocks in advanced MCCI engines for MD and HD vehicles has shown alkanes, cyclic alkanes, alkenes, ethers, polyethers, and esters to be promising candidates.

Pairing Fuels and Engines Innovation for LD, MD, and HD Solutions

Research explored options that pair these blendstocks with combustion solutions including:

- Boosted SI and multimode approaches for LD vehicles targeting a 10% improvement in fuel economy. This is beyond an already expected 25% improvement in fuel economy for engine-only advances anticipated through 2025 (reference case is a 2015 baseline).

- MCCI for MD and HD trucks targeting a 50% reduction in engine-out criteria pollutant emissions (compared to a 2009 baseline).

- ACI for the full range of vehicle classes targeting 60% brake thermal efficiency with a 50% reduction in engine-out criteria pollutant emissions (compared to a 2009 baseline).

Light-Duty Vehicle Technical Targets

Fuel economy improvement beyond an already expected 25% improvement in fuel economy for engine-only advances anticipated through 2025 (reference case is a 2015 baseline).

Medium-Duty and Heavy-Duty Vehicle Technical Targets

More information on Co-Optima research goals, activities, and accomplishments can be found in the final findings and impact report.

Program Contacts

For more information on the Co-Optima initiative, contact the project leadership team.