With the help of DOE funding, the University of California, Los Angeles has been working to develop an integrated plastic substrate to replace the use of indium tin oxide (ITO) on glass for the fabrication of white OLEDs. In addition to seeking a replacement for high-cost ITO and display-grade glass, the project seeks to enhance light extraction through economical methods internal and external to the substrate.

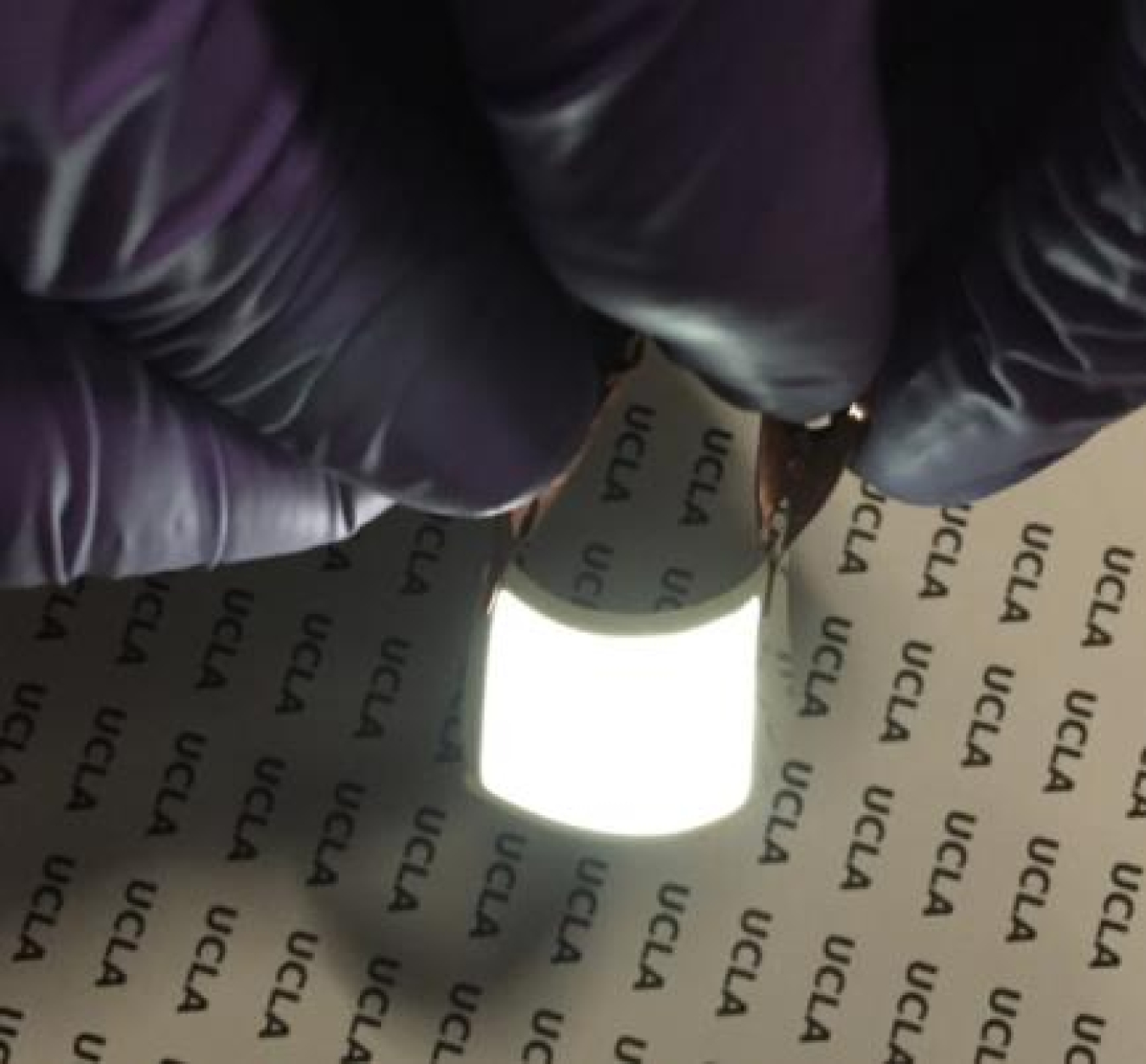

UCLA’s approach uses a silver-based nanowire network within the plastic substrate. Through a solution-based coating process, the goal is to exhibit surface conductivity at least matching that of ITO on glass. Success to date has led to the combined properties of low sheet resistance (~5 ohm/sq), low surface roughness (Ra < 2nm), and a twofold extraction enhancement of control device on ITO/glass. UCLA continues to improve on these properties through the DOE-sponsored research, and so far has achieved a flexible warm-white OLED with an efficacy > 100 lm/W at 1000 cd/m2 brightness, without the use of any additional light-extraction structures.

UCLA has also taken advantage of DOE’s OLED Testing Opportunity and reports that it’s proven useful in advancing the new substrate technology. The feedback from the testing has provided significant input to steer project direction and to improve performance. In addition to benefiting UCLA’s research project, the testing opportunity has provided the testing laboratory with valuable insight into the handling and processing of “flexible” substrates as compared to rigid glass. (September 2016)

Return to Research Highlights.