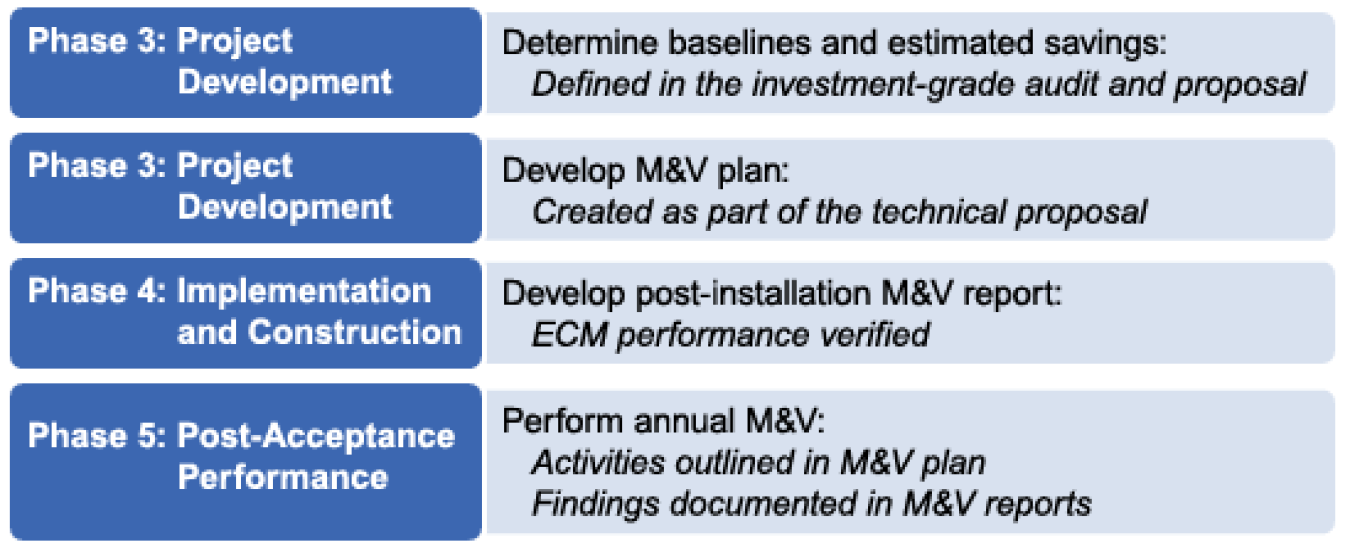

M&V activities span three phases of the the ESPC process.

There are four major measurement and verification (M&V) activities in the federal energy savings performance contract (ESPC) process. They include:

- Determining baselines and estimated savings

- Developing the M&V plan

- Developing the post-installation M&V report, which is part of conducting post-installation M&V activities

- Performing annual M&V, which is part of the conducting annual M&V activities.

Baselines are compared to post-installation energy use to determine savings. Typically the energy service company (ESCO) defines the baselines as part of the investment-grade audit (IGA). Baseline physical conditions (such as equipment inventory and conditions, occupancy, nameplate data, energy consumption rate, and control strategies) are characterized through IGA surveys, inspections, spot measurements, and short-term metering activities.

Baseline conditions are established to calculate savings by comparing the baseline energy use to the post-installation energy use. Baseline data are also used to account for any changes that may occur during the performance period that could require baseline adjustments. The baseline data are included in the ESCO’s proposal. It is the agency’s responsibility to ensure that the baseline has been properly defined.

In almost all cases, after the energy conservation measure (ECM) has been installed, it is impossible to re-create the baseline. Therefore, it is very important to properly define and document the baseline conditions. Deciding what needs to be monitored, and for how long, depends on factors such as the complexity of the measure and the stability of the baseline, including the variability of equipment loads and operating hours, as well as other variables that affect the load.

Learn more about establishing baselines and investment-grade audits in phase 3 of the federal energy savings performance contract process.

The M&V plan is the single most important item in an energy savings “guarantee.” Although the M&V plan is usually developed during contract negotiations, it is important for the agency and the energy service company to agree on a general M&V approach before starting the investment-grade audit, because the M&V methods chosen will significantly affect how the baseline is defined, which will determine which activities are conducted during the IGA.

The project-specific M&V plan includes project-wide items as well as details for each ECM, including:

- Details of baseline conditions and data collected

- Documentation of all assumptions and sources of data

- What will be verified

- Who will conduct the M&V activities

- Schedule for all M&V activities

- Details of engineering analysis performed

- How energy savings will be calculated

- Utility rates and how they will be used to calculate cost savings

- Details of operations and maintenance (O&M) cost savings claimed

- Defined O&M reporting responsibilities

- Defined content and format of all M&V reports

- How and why the baseline may be adjusted.

Best Practices for Developing the Measurement and Verification Plan

- Understand the energy service company's perspective. The ESCO is guaranteeing performance and may not see closer inspection (more M&V) to be in its interest.

- Recognize that the goal is to reduce uncertainty in savings, but that adding M&V adds cost. M&V should balance cost and uncertainty. More complex ECMs usually merit more M&V.

- Make sure that ESCO-proposed baselines and fixed parameters for ECMs are sound, because they are the cornerstones of the savings calculations.

Measurement and Verification Plan

FEMP provides documents to help agencies and ESCOs develop an M&V plan.

- Example Measurement and Verification Plan for an ESPC Project

- Measurement and Verification Plan and Savings Calculations Methods Outline (IDIQ Attachment J-8)

- Reviewing Measurement and Verification Plans for Federal ESPC Projects

Learn more about how the measurement and verification plan fits into phase 3 of the federal energy savings performance contract process.

Post-installation verification is conducted by the ESCO and the federal agency to ensure that proper equipment and systems were installed, are operating correctly, and have the potential to generate the predicted savings. The verification is accomplished through commissioning and M&V activities.

Post-installation M&V activities specified in the M&V plan may include surveys, inspections, spot measurements, and short-term metering. The results of the M&V activities are presented in a Post-Installation Report Outline delivered by the ESCO before final project acceptance.

Measurement and Verification Report

The Federal Energy Management Program provides documents ESCOs can use to develop M&V reports.

- Reviewing Post-Installation and Annual Reports for Federal ESPC Projects

- Post-Installation Report Outline (IDIQ Attachment J-9)

- Annual Report Outline (IDIQ Attachment J-10)

- Guide to Government Witnessing and Review of Measurement and Verification Activities

Learn more about how the post-installation measurement and verification report fits into phase 4 of the federal energy savings performance contract process.

At least annually, the ESCO and the federal agency verify the installed equipment and systems have been properly maintained, continue to operate correctly, and continue to have the potential to generate the predicted savings. Although an Annual M&V Report (using the Annual Report Outline) from the ESCO is required to substantiate savings guarantees, more frequent verification activities can be appropriate. This ensures the M&V monitoring and reporting systems are working properly, allows fine-tuning of measures throughout the year based on operational feedback, and avoids surprises at the end of the year.

Best Practices for Annual Measurement and Verification during the Performance Period

- Agencies should designate a primary contact who is responsible for:

- Maintaining contact with FEMP through the life of contract program

- Maintaining continuity of documentation and awareness of the ESPC throughout the performance period.

- Agencies should designate a government witness to accompany the ESCO during annual measurement and verification activities. Ensure the government witness has reviewed current FEMP guidance on M&V witnessing. COR delegation letters should include designation of the contracting officer as M&V witness.

- Agencies should put procedures in place to ensure prompt review of the ESCO's annual M&V report, in accordance with FEMP guidance. The annual M&V report must be in accordance with the M&V plan in the task order. These reports document whether all parties and the delivered energy and cost savings meet the task order requirements.

- In the case of demolished or decommissioned buildings or removal of ECM equipment by the government, the agency contracting officer should promptly initiate a contracting action to buy out that part of the contract involving ECMs that are no longer in place or no longer functional.

Learn more about how annual measurement and verification fits into phase 5 of the federal energy savings performance contract process.

- Agencies should designate a primary contact who is responsible for:

Learn More About Measurement and Verification

Information is available about the following M&V topics.

- M&V options for ESPCs.

- Using M&V to manage risk in energy- and water-saving projects.

- Types of energy and water cost savings that can be used to pay for a project.