The U.S. Department of Energy (DOE) Solar Energy Technologies Office (SETO) supports research and development projects that increase the efficiency and lifetime of metal-halide perovskite solar cells, speeding the commercialization of perovskite solar technologies and decreasing manufacturing costs.

What is a perovskite solar cell?

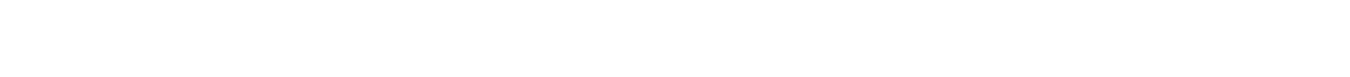

Perovskites are a family of materials that have shown potential for high performance and low production costs in solar cells. The name “perovskite” comes from their crystal structure. These materials are utilized in other energy technologies, such as fuel cells and catalysts. Perovskites commonly used in photovoltaic (PV) solar cells are more specifically called “metal-halide perovskites” since they are made of a combination of organic ions, metals, and halogens; perovskites in other applications may be made of oxygen instead of halogens and are usually entirely inorganic.

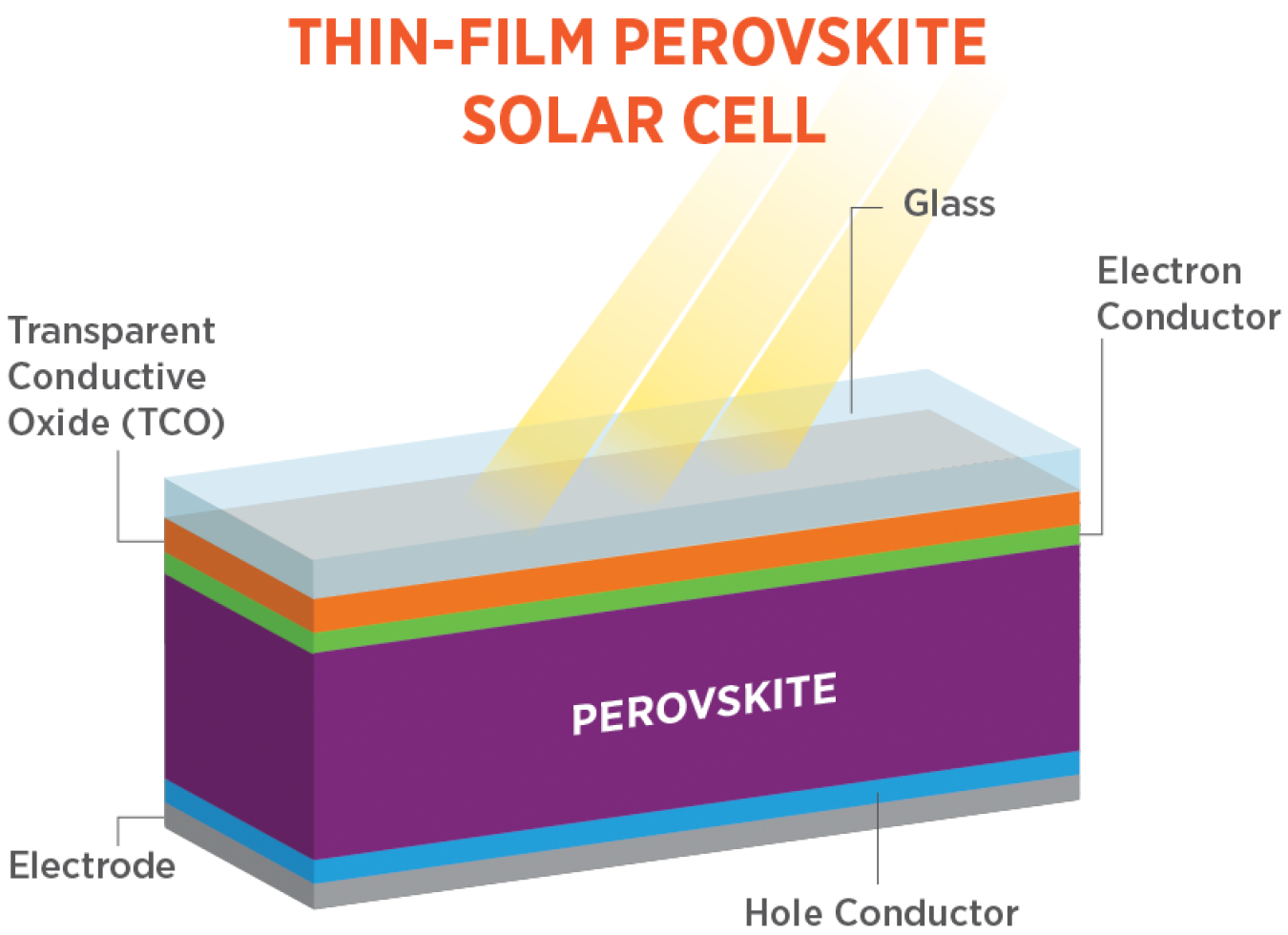

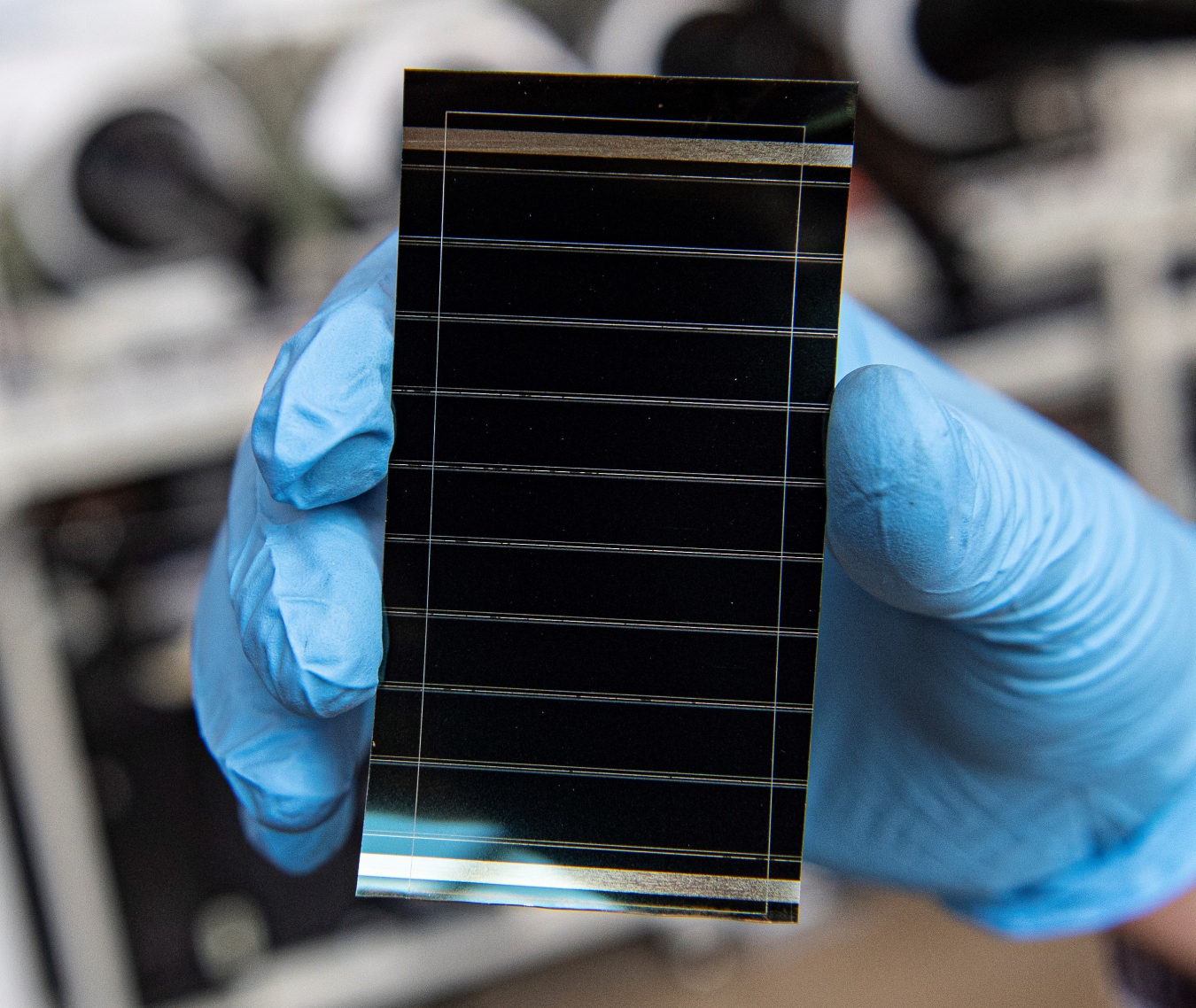

Metal-halide perovskites are the main absorbing material, or “active layer,” in a perovskite solar cell. In this potentially inexpensive technology, a thin layer of perovskite absorbs light, which excites charged particles called electrons; when these excited electrons are extracted, they generate electric power. Perovskite cells are referred to as thin-film because they require much thinner active layers relative to crystalline silicon PV.

This is possible due to perovskite’s ability to absorb certain colors of light very effectively. Perovskite absorber layers can also be stacked on top of another absorber layer, such as silicon, to use the colors of light not absorbed in the perovskite, resulting in a cell that can be theoretically more efficient than cells made of either material on their own. When two layers are stacked in such a manner, this is known as a tandem solar cell.

In a solar cell, the perovskite absorber is attached to other materials, which “force” electric current to flow in a single direction through the absorber layer and into the metal contacts to be collected as electric current. Learn more about how solar cells work.

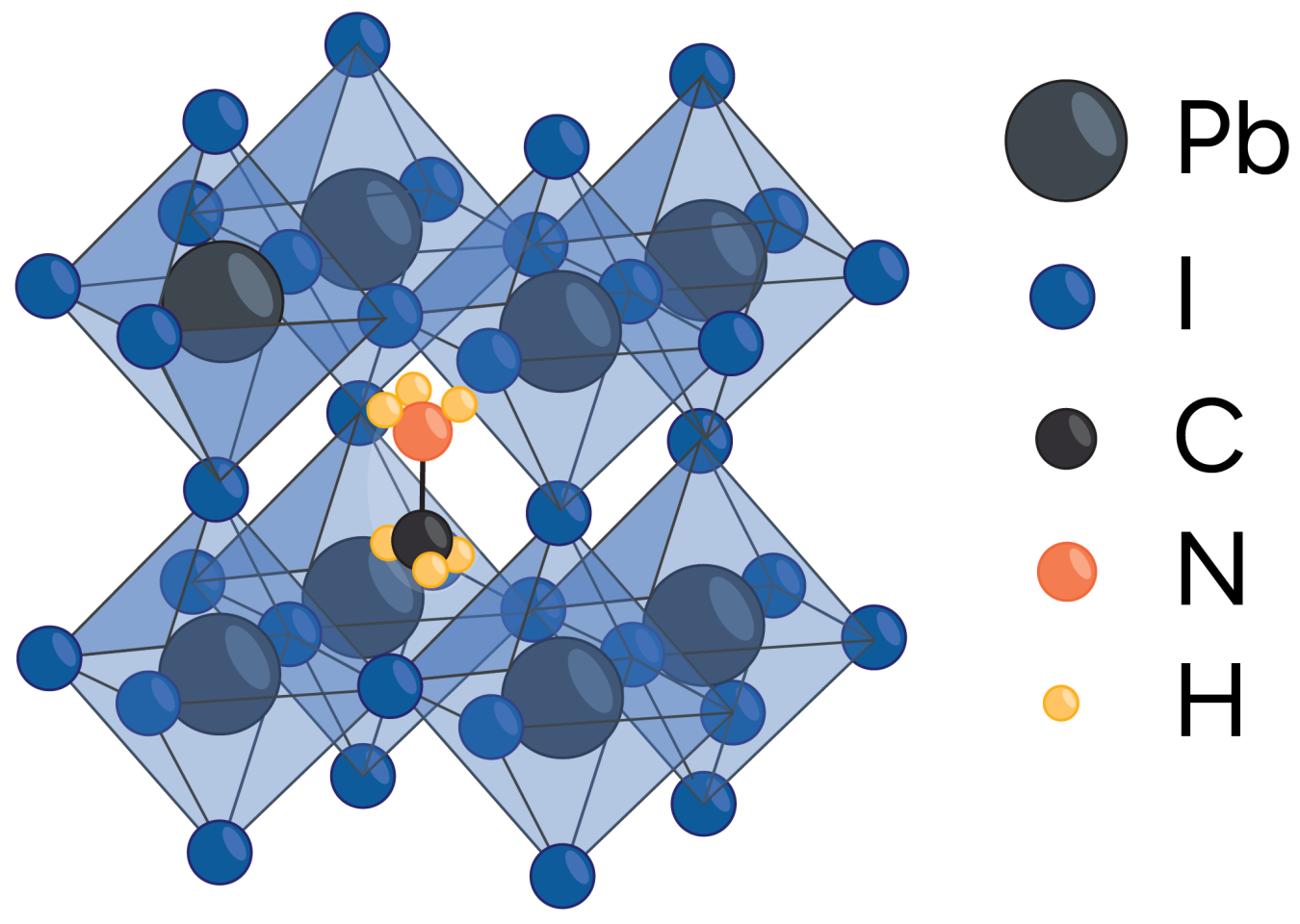

Perovskite solar cells have shown remarkable progress in recent years with rapid increases in efficiency, from reports of about 3% in 2009 to over 26% today on small area devices (about 0.1 cm2). Perovskite-silicon tandem cells have reached efficiencies of almost 34%. While perovskite solar cells have become highly efficient in a very short time, perovskite PV is not yet manufactured at scale and a number of challenges must be addressed before perovskites can become a competitive commercial PV technology.

How are perovskite solar technologies made?

Below is a general overview of the general steps taken to produce perovskite solar cells and modules. Because the technology is still in development, the details of each step can vary widely between research groups. This includes the elements that comprise the perovskite materials, cell and module assembly, and the tests performed on the finished product.

Material creation

Precursor salts are mixed to form a perovskite ink solution. In some cases, if the material will be deposited as a vapor, the salts are not mixed until they are deposited together on a cell in the next step.

Cell production

An ultra-thin layer of perovskite ink or powder is deposited onto a base. The cell is heated to set the film. Other material layers are deposited before (and below) the perovskite layer, or after (and on top of) the perovskite layer. These layers help direct the flow of electrons.

Module completion

If a module is to be created, channels are laser scribed to separate the film into individual cells. Electrical contact channels are scribed to wire those cells together. Edge sealant and encapsulant for weather proofing are added.

Testing and development

The cell or module is tested to gauge its efficiency and durability. Since perovskites are not yet in high-volume production, the knowledge gained regarding its materials and electronic properties will be used for further research and development.

What are SETO research priorities in perovskites?

SETO has identified four primary challenges that must be simultaneously addressed for perovskite technologies to bridge the gap between lab research and commercial success: cell stability and durability; power conversion efficiency at scale; manufacturability; and technology validation and bankability. Read more about these challenges.

SETO supports projects that address these challenges through several funding programs:

- Advancing U.S. Thin-Film Solar Photovoltaics

- Small Innovative Projects in Solar (SIPS)

- Photovoltaics Research and Development (PVRD) Funding Program

- SETO Fiscal Year 2022-24 Lab Call

- SETO Fiscal Year 2020 Perovskite Funding Program

You can also read SETO's perspective on the path to perovskite commercialization and review the findings of SETO's Performance Targets for Perovskite Photovoltaic Research, Development, and Demonstration Programs Request for Information. DOE hopes to develop targets for hybrid tandem technologies by the end of 2026.

What are the potential benefits of perovskite solar technology?

| Low-Cost Potential | Perovskite PV cells are made using low-temperature processes and with the potential for ink-based printing of active layers. This may allow for more integrated manufacturing comprising of fewer, less expensive process steps and lower capital expenditure. |

| Use in Tandem PV Cells | Perovskite absorber material can be stacked on top of a silicon absorber, which can convert light to electrical power more efficiently than either technology separately. Also, by changing the color of light absorbed by the perovskite (band gap), perovskites can be engineered to pair with many other solar materials in tandem solar cells and modules. |

| Defect Tolerance | Perovskites appear to be more resilient to imperfections in their crystal structure relative to other conventional semiconductors. |

| High Efficiency | Perovskite material is able to convert light to electrical power at a similar efficiency to silicon. |

Learn more about SETO’s PV research, how PV technologies work, and perovskite research directions.